|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Gears | >Careful calculation required |

Careful calculation required

17 April 2025

Patrick Faulkner explores the importance of gear ratios in optimising performance and efficiency

GEAR RATIOS are crucial for optimising the functionality and performance of machinery. Whether in manufacturing or heavy industries, they are key to ensuring equipment operates efficiently.

What are gear ratios?

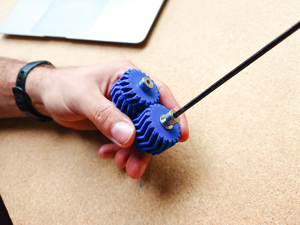

A gear ratio defines the relationship between two meshing gears by comparing the number of teeth on the driving (input) gear to the driven (output) gear. The calculation is presented as Gear Ratio (GR) = Number of Teeth on Driven Gear (T2) / Number of Teeth on Driving Gear (T1).

This ratio determines how many revolutions the driving gear must make to turn the driven gear once. For instance, a 3:1 gear ratio means the driving gear rotates three times for each rotation of the driven gear.

This principle plays a crucial role in the design and operation of various mechanical systems, as changing the gear size and number of teeth allows for customisation to meet specific performance requirements.

Why are gear ratios important in manufacturing?

Gear ratios play a crucial role in machinery and manufacturing processes by directly impacting speed, power and efficiency. This allows manufacturers to fine-tune performance to meet specific operational needs.

For example, in high-speed production lines, a lower gear ratio facilitates faster output rotations and ensures that machinery operates at maximum speeds that increasing output.

Conversely, in heavy-duty applications like material handling, a higher gear ratio provides the necessary torque to move large loads with minimal energy consumption, preventing unnecessary wear and tear on components.

By increasing or decreasing the gear ratio, design engineers can manipulate the speed and torque output, balancing efficiency and performance in relation to productivity.

Gear ratios can also be used to change the direction of rotation, which is fundamental in machinery that requires movement in opposite directions for operation. In precision applications like robotics and CNC machining, selecting the right ratio ensures smooth, controlled movements, enhancing accuracy and reliability.

In automated manufacturing and industries that run 24-7, achieving the right balance between speed and torque is critical for maintaining workflow consistency. A poorly optimised gear ratio can lead to inefficiencies, such as excessive wear on components, increased downtime for maintenance and energy wastage.

How to calculate gear ratios

Calculating gear ratios requires an understanding of the relationship between two gears: the input gear and the output gear. By adjusting the gear ratio, engineers can fine-tune machinery to achieve the right balance of speed, torque and efficiency for specific tasks.

For example, if the input gear has 20 teeth and the output gear has 40 teeth, the gear ratio would be 2:1. This means the output gear will rotate at half the speed of the input gear, but it will generate double the torque.

On the other hand, if the input gear has 40 teeth and the output gear has 10 teeth, the gear ratio would be 1:4. This means the output gear will rotate four times faster than the input gear, but it will generate only a quarter of the torque.

Knowing how to calculate and interpret gear ratios is crucial for optimising machinery performance.

With conveyor belts, for example, the right gear ratio helps maintain a steady production flow, whereas robotics applications utilise higher ratios for precise and controlled movements.

Patrick Faulkner is lead engineer at Accu