|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Pneumatics & Hydraulics | >How energy efficient is your compressor? |

How energy efficient is your compressor?

08 August 2025

SWITCHING TO an energy-efficient air compressor can help you significantly reduce costs. Find out how...

Due to the steep and rapid increase in energy costs, today’s manufacturing and business environments need to employ smart energy cost reduction strategies to remain competitive.

This means facility engineers are tasked with optimising the energy efficiency of their operations, and extracting as much productivity out of every unit of energy paid for and consumed, as possible.

Compressors and energy use

Historically, compressed air systems have been a major component of industrial energy consumption. In fact, it is estimated that air compressors account for more than 10% of the total energy consumed by UK industry.

Switching to the most energy-efficient air compressors, then, can help to reduce energy and costs.

To spot the most energy-efficient compressors in the market, it is vital to understand Specific Power.

What is specific power?

Specific Power is the ratio of total energy used by the compressor and its compressed air output (at a stated pressure).

The lower the Specific Power of a compressor, the greater the efficiency, and the higher the energy and cost savings.

The total energy used by the compressor is the total power input at the maximum stated pressure, and includes the main motor, fan motor(s) and their efficiencies, and any other compressor power requirements.

The compressed air output typically described as Free Air Delivery, is the compressed air volume at the outlet of the compressor package at atmospheric pressure.

How is specific power calculated?

The Specific Power of a compressor is the energy used divided by the compressed air output.

Using this calculation, we can see that the HPC KAESER ASD40 7.5 bar rotary screw compressor’s Specific Power is 5.92kW/m3/min:

23.2kW (Energy Used) ÷ 3.92m³/min (Compressed Air Output) = 5.92kW/m3/min (Specific Power)

Equivalent non-HPC compressors are typically less energy efficient with a higher Specific Power, exceeding 7.0kW/m3/min.

How does this save money?

The cost saving can be calculated by multiplying the Specific Power by the total volume of compressed air, by the cost per kWh.

Based upon a 2-shift operation when compressed air is needed for 4000 hours per annum, we can calculate the approximate compressed air costs for a non-HPC equivalent compressor:

7.19kW/m3/min (Specific Power) x 4000 hours x 3.65m³ (Total Volume Compressed Air) x £.30kw/hr (Cost Per kWh) = £31,492 (Costs P.A).

Compared to the ASD40, which would only need to run 3725 hours to produce the same volume of compressed air:

5.92kW/m3/min (Specific Power) x 3725 hours x 3.92m³ (Total Volume Compressed Air) x £.30kw/hr (Cost Per kWh) = £25,933 (Costs P.A).

HPC saves £5559 per annum

This means investing in an HPC KAESER energy efficient compressor, with market-leading Specific Power - and less running time - saves you money in the long-term.

In fact, we save our customers up to £25k a year – and in some cases, much more than that.

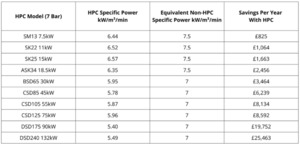

Fig 1. Examples of energy cost savings, based upon 2,000 hours (single shift operation)

Many other brand manufacturers entice customers on the pretext of cheaper priced compressors. While this may offer an initial outlay saving, customers will end up paying many times more over this difference in unnecessary energy costs.

With further increases in energy costs on the horizon, reducing energy bills matters more now than ever.