|

Charlotte Stonestreet

Managing Editor |

Gearing up for precision performance

21 October 2025

Mike Gulliford examines the major types of precision servo gearboxes, what they are used for and how they are evolving

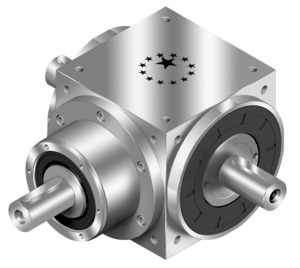

GEARBOX SELECTION is a delicate balance to achieve the optimal result for each application, and gearboxes often determine the performance and reliability of the entire system. Precision gearboxes come in a variety of configurations, each designed to optimise specific performance characteristics such as torque density, backlash, efficiency, and compactness. Understanding their differences is essential when selecting a gearbox for robotics, automation, aerospace, medical equipment, or other high-performance applications. This article explores the most prominent types of precision gearboxes – planetary gearboxes, harmonic drives, cycloidal drives – as well as hybrid and emerging architectures that push beyond traditional designs.

Planetary Gearboxes

Planetary gearboxes, also known as epicyclic gear trains, are among the most common precision gearbox designs. Their compactness and ability to transmit high torque relative to their size make them a preferred choice in industrial robotics, machine tools, and servo-driven systems.

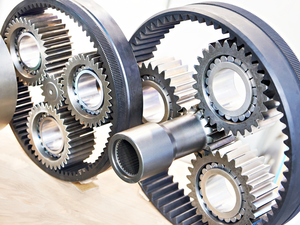

A planetary gearbox consists of three main elements:

- A sun gear at the centre

- Multiple planet gears orbiting around the sun, typically mounted on a carrie

- A ring gear with internal teeth that mesh with the planets.

Torque transmission occurs through this shared load distribution, with several planet gears simultaneously engaged, resulting in high power density.

Advantages:

- High torque-to-weight ratio

- Low backlash achievable with precision manufacturing

- Excellent load distribution and durability

- Coaxial input and output shafts for compact integration.

Limitations:

- Moderate gear reduction ratios per stage (typically 3:1 to 10:1)

- Efficiency losses increase with multiple stages

- More complex manufacturing compared to spur or helical gearboxes

Planetary gearboxes are widely used in industrial automation, packaging machinery, robotic arms, and aerospace actuators.

Harmonic/strain wave drives

Harmonic drives, also known as strain wave gears, are prized for their extremely low backlash and high reduction ratios in a compact package. First developed in the 1950s, they remain a cornerstone in robotics, especially in articulated joints requiring precision and repeatability.

The system typically comprises three components:

- A circular spline (rigid, with internal teeth)

- A flex spline (a thin, deformable cup with external teeth)

- A wave generator (an elliptical cam or bearing assembly that flexes the flex spline into engagement with the circular spline)

As the wave generator rotates, it deforms the flex spline, causing its teeth to engage and disengage gradually with the circular spline. This differential tooth count results in large gear reductions.

Advantages:

- Near-zero backlash

- Very high gear ratios in a single stage (up to 320:1)

- Lightweight and compact relative to torque capacity

- High positioning accuracy.

Limitations:

- Lower efficiency under continuous duty compared to planetary or cycloidal drives

- Flex spline fatigue limits lifespan under heavy or shock loads

- Less suitable for very high-speed input

Applications for harmonic drives include robotic joints, aerospace pointing systems, surgical robots and semiconductor equipment.

Cycloidal gearboxes

Cycloidal drives, also called trochoidal gearboxes, are known for their robustness, shock load tolerance, and ability to deliver high reduction ratios with durability. Unlike traditional gears with involute tooth profiles, cycloidal mechanisms use rolling motion for torque transfer.

Key components include:

- An eccentric cam that drives a cycloidal disk

- The cycloidal disk has lobes that roll against pins in the housing

- Output rollers or pins capture the motion and transmit torque to the output shaft.

The rolling action results in smooth motion and reduced stress concentration.

Advantages:

- Very high reduction ratios in compact form

- High shock-load resistance (up to five times rated torque)

- Low backlash achievable

- Long operational life due to rolling contact

Limitations:

- More complex mechanical structure than planetary gears

- Higher vibration levels at certain speeds

- Efficiency slightly lower than planetary designs under continuous duty.

Some common applications for cycloidal gearboxes include robotic bases and arms, heavy machinery, machine tools and indexing tables.

Hybrid and emerging architectures

As the demand for higher precision, greater energy efficiency, and smaller footprints increases, gearbox manufacturers are experimenting with hybrid and novel architectures that combine the strengths of multiple technologies.

Some examples of emerging designs include:

- Planetary-Harmonic Hybrids: Combining planetary stages for torque density with harmonic stages for precision and high ratios.

- Cycloidal-Harmonic Hybrids: Using harmonic stages for low backlash with cycloidal stages for durability under shock loads.

- Magnetically Assisted Drives: Incorporating magnetic gears to reduce wear and noise.

- Additive-Manufactured Architectures: 3D printing enables complex internal geometries, weight reduction, and integrated cooling channels.

- Direct-Drive Alternatives: While not gearboxes in the traditional sense, high-torque direct-drive motors are increasingly competing with mechanical transmissions where backlash elimination is critical.

Advantages of emerging gearbox technologies include tailored performance for specialised applications and the ability to mitigate the trade-offs associated with conventional gearboxes. They open new pathways for compact, lightweight and maintenance-free systems. However, newer solutions often come with higher costs and complexity and reliability is still be validated for many designs.

In areas such as next-generation robotics, aerospace control systems, the emerging market for medical micro-robots, and precision optical equipment, emerging gearbox technologies may provide new opportunities and applications in the future.

Final thoughts

Each gearbox type offers unique benefits and trade-offs. Planetary gearboxes provide versatile, well-rounded performance. Harmonic drives dominate in the precision robotics sector due to their compactness and zero-backlash characteristics. Cycloidal gearboxes excel in high-shock and heavy-duty applications. Hybrid and emerging solutions seek to combine these strengths, reflecting the evolving demands of modern engineering.

Mike Gulliford is managing director of Apex Dynamics UK

This article is adapted from a chapter of Servo Gearbox Secrets 2025: The Definitive Guide to Specifying and Applying Precision/Servo Gearboxes in Motion Control Projects, a book written by Apex Dynamics UK managing director, Mike Gulliford. It provides a valuable resource for anyone involved in motion control projects, containing Mike’s extensive knowledge about gearboxes, their specification and application, gathered throughout a long and successful career.

- Apex Dynamics unveils first couplings range

- Inline planetary gearbox for waterwheel control

- Zero backlash precision couplings

- High speed, high precision

- Gearboxes for AGV applications

- Designed for enhanced axial and radial loads

- Planetary gearbox series expanded

- Break-in fails to stop gearbox specialist's business growth

- Seamless and transparent integration

- Five-minute challenge

- No related articles listed