|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Gearboxes | >Seamless and transparent integration |

Editor's Pick

Seamless and transparent integration

11 November 2024

Apex Dynamics UK has been praised by Cambridge Dynamics for the "seamless and transparent" implementation of its products into a new custom machine the specialist company produced for one of its customers.

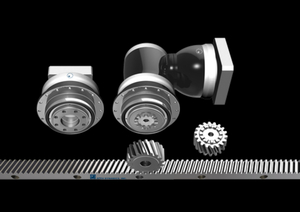

THE BESOKE project used a series of Apex Dynamics precision planetary gearboxes and rack and pinion sets to provide the torque needed to facilitate highly accurate movement and positioning of a table axis.

Cambridge Dynamics designs and assembles high-end specialised, custom machinery and bespoke automation solutions, supplying a wide range of industry sectors, from aerospace and automotive to food and beverage, technology and general manufacturing businesses. The business was contracted to design and build a replacement machine by its customer, which creates custom parts for companies. The machine to be replaced was built decades ago and had reached end of life. It is used to cut customised profiles into 3mm stainless steel plates used in distilling and brewing processes.

Precision engineered

Each plate is precision engineered and tooled with hundreds of individual slits. They are placed on top of a large bed on the machine and bolted down. A rack set down either side is powered by a servo motor and gearbox and drives a cutting head down the bed. It has eight slitting saws on it and cuts slots into the plate. The bottom of each slot is opened up to create a gap so that the plate can act as a filter to prevent solid matter going through.

Cambridge Dynamics turned to Apex Dynamics to supply gearboxes and rack and pinion sets for the custom project. Apex’s AFR right angled planetary gearboxes fitted the bill. Combined with the company’s Mod 2 Quality 6 high precision helical rack and pinion set, they provided the highly accurate movement and positioning of the table axis required. Several gearboxes were needed to achieve the required torque. Apex’s products fitted perfectly into the bespoke design. All the racks were produced to length and, although Cambridge Dynamics has purchased custom gearboxes from Apex Dynamics before, there were no modifications or customisation needed this time.

The robust, lightweight Apex AFR series has a 90° input via 100% optimised helical bevel gearing and full compatibility with standard motor adapters. It delivers high precision, high torque and quiet operation, while its high precision taper roller bearings are capable of handling high axial and radial loads.

Long life, high performance

Alongside the AFR gearboxes, Apex Dynamics’ high precision, low noise rack and pinion systems are manufactured to meet Quality 4 standards. Tooled underground to ensure the best-possible temperature control and quality, the rack and pinion sets supply high speed and very low tolerance, alongside long life and high performance on the axis.

Cambridge Dynamics reports that the implementation process was “seamless and transparent” and the company has never had any problems with delivery and installation of Apex Dynamics products. André Becker, Cambridge Dynamics managing director added Apex Dynamics has always been “very helpful” and this has been a very good and successful project, with the customer happy and the machine signed off easily.

The new machine is replacing the customer’s previous machine with much more modern technology and all the benefits of modern safety certification and standards. It is also expected to improve cycle times by around 50% in comparison with the old device.

- Apex Dynamics unveils first couplings range

- Precision planetary gearboxes

- ATEX-certified precision planetary gearboxes

- Inline planetary gearbox for waterwheel control

- Gearing up for precision performance

- Zero backlash precision couplings

- Designed for enhanced axial and radial loads

- Planetary gearbox series expanded

- Five-minute challenge

- Gearboxes for AGV applications

- GEARBOX IS CHEAPER TO REPLACE THAN REPAIR

- PLANETARY/SPUR GEARBOXES

- PLANETARY GEARS WELL SUITED FOR RETROFIT

- AGEING WORM GEARS REPLACED BY PLANETARY GEARS IN SEWAGE PLANT

- REHFUSS BRINGS QUALITY AND VERSATILITY TO GEARBOX DESIGN AND SELECTION

- FLEXIBLE COUPLINGS

- GETTING THE BEST OUT OF GEARBOXES

- A Guide to the Selection

- Greater Corrosion Resistance

- Fits existing parameters