|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Machinery Safety | >Safety through collaboration |

| Home> | AUTOMATION | >Robots | >Safety through collaboration |

Safety through collaboration

27 April 2022

LAUNCHING A new range of innovative robotic flexible manufacturing cells at Mills CNC would not have been possible without safety integration from SICK that helps to maximise productivity, while enabling operator collaboration. Neil Sandhu reports

On their journey to Industry 4.0, many manufacturers are instinctively cautious about integrating flexible cells into their production workflows: Can I find the extra space to accommodate the robot cell? Will constant e-stops reduce productivity and therefore make investment unviable? Will the integration be too complex, time-consuming, or costly?

For Warwickshire-based machine tool specialist Mills CNC, these are common questions posed by prospective customers for its automated robot systems to tend the Doosan lathes, milling machines and machining centres, for which it is the exclusive UK distributor.

Integrating compliant machine safety successfully into its new SYNERGi Premier flexible robotic machine cells was therefore essential – but could have been particularly challenging given the relatively high degree of human interaction with the cell.

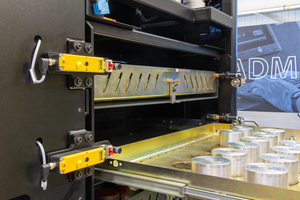

Chris Ingham, control and system engineer for Mills CNC explains: “The new SYNERGi Premier flexible robot cells have a two-way loading/unloading station with five automated drawers. Even at this increased level of automation, operator involvement is inevitable to interact with the Fanuc robot that is continuously feeding the machine.

“Working outside the cell, operators load up workpieces and remove machined components through the two-way automated drawers. Meanwhile, the robot operates continuously inside the cell, taking workpieces out of the drawers and feeding the machine, before replacing the machined component back into the drawer. Setters must enter the robot cell periodically to service the machine tool itself.

“With automated machine tending systems, the key objective is to keep the robot going for production efficiency, while having the flexibility to change the parts in and out,” Ingham continues. “Our custom HMI software allows you to load as many parts in the tray as you so wish or run all five trays out in one go. It truly is a fully flexible solution.

“You can then employ staff much more efficiently on the shop floor because operators and setters can be deployed across several cells, as well as performing other duties.”

Mills CNC turned to machinery safety specialists at SICK and together they worked to integrate safety systems that enable productivity and maximum uptime, while being completely transparent for the user.

“Implementing SICK’s network safety has been a massive game-changer for us in bringing the machines to market,” says Ingham. “Less sophisticated systems would have required a complete shutdown whenever the robot and operator inhabited the same space, requiring a reset and restart. They would have also required complex wiring that could have been difficult, if not impossible, to implement.”

Safety was a game-changer

All Mills CNC’s automated SYNERGi flexible manufacturing cells are fitted with the latest SICK sensor hardware. Each of the five automated drawers of the SYNERGi Premier system is fitted with a SICK TR110 safety interlock with guard locking. A SICK microScan3 safety laser scanner is positioned at the foot of the robot to allow safe access for setters into the machine cell.

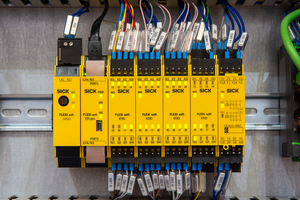

At the heart of the safety concept is the SICK EFI Pro network technology that supports direct integration of the SICK sensors and the robot controls via Ethernet/IPTM CIP SafetyTM up to SIL3/PLe.

“The number one challenge for us was finding a system that could talk natively, using the same protocols as the robot,” Ingham explains. “Without the direct connection through the SICK EFI-Pro system over a single Ethernet cable, the integration would have been much more difficult, and more costly.

“The SICK TR110 interlock interacts directly with the Fanuc Dual Check Safety (DCS) control architecture of the robot cell system via CIP Safety. The DCS system enables me to draw 3-dimensional boxes around the drawer catches to restrict the movement of the robot and ensure clearance for the operator.”

The Safe EFI-Pro system is SICK’s safety network for industrial automation, based on the CIP Safety protocol. It enables safe communication between SICK EFI-Pro devices like the microScan3, other SICK sensors, and third-party CIP-SafetyTM devices like robot controllers, through the SICK Flexi Soft safety controller and a SICK EFI-Pro gateway. The SICK EFI-Pro system also enables full remote diagnostics so that the system’s performance is recorded and monitored.

Mills CNC opt to use the 9-metre range microScan3 Core using SICK Safe HDDM multiple scanning technology on all their SYNERGi systems to control safe access for setters into the cell. The SICK safety system enables the scanner to be used as the primary safety device with two protective fields to slow the robot down before it enters a full stop.

The SICK Safe EFI-Pro system enables safe human and robot collaboration with minimal effort. High-performance simultaneous protective monitoring of multiple fields means less switching between monitoring cases, so dynamic protective fields can be shorter, and therefore more responsive and efficient.

Floor space minimised

“Sometimes we have to shoehorn a machine into a very small footprint,” says Ingham “With the microScan3 you can minimise the floor space and by slowing the robot down and enabling continued operation, you are increasing productivity dramatically. The alternative would have been a fully enclosed cell and reduced uptime.

“Thanks to the SICK dynamic EFI-pro system, the fields can be set closer in, to take up less floor space, and the robot can continue to operate safely for as long as possible, so maximum uptime is maintained.”

SICK UK’s National Machinery Safety Product Manager, Martin Kidman, explains: “Downtime is the enemy of any production process. Mills CNC have demonstrated a masterclass in delivering productivity through safety in their new SYNERGi automated manufacturing cells. With the benefit of the SICK safe EFI-Pro dynamic network safety, we have been able to work in partnership to engineer a complex system from a safety point of view, that achieves ease and simplicity with seamless integration for Mills CNC customers.”

Neil Sandhu is product manager for imaging, measurement and ranging at SICK UK

Key Points

- When Mills CNC needed integrated safety systems that enable productivity and maximum uptime, it turned to SICK for a solution

- All Mills CNC’s automated SYNERGi flexible manufacturing cells are fitted with the latest SICK sensor hardware

- SICK EFI Pro network technology supports direct integration of SICK sensors and robot controls via Ethernet/IPTM CIP Safety up to SIL3/PLe

- Intelligent solutions showcased

- Sensor for 3D detection

- On-premise data intelligence platform

- Miniature vision sensor sets new 3D standards

- Enhance safety and productivity with muting module

- Harnessing power of AI

- Easy vision robot guidance

- Powerful and compact cube sensor

- PROGRAMMABLE ENCODER ADVANTAGES - GIVE ME FIVE

- 3D LiDAR navigation and collision avoidance

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- MAKING SENSE OF SAFETY

- NUMBER OF ROBOTS IN UK ON THE RISE

- Handwheel Valve Position Indicators

- The future is bright - The future is automation!

- High Demand For Grant

- More Capacity, Less Space

- Modular Heavy Duty Interlocks