|

Charlotte Stonestreet

Managing Editor |

igus introduces new speedifit service

23 April 2013

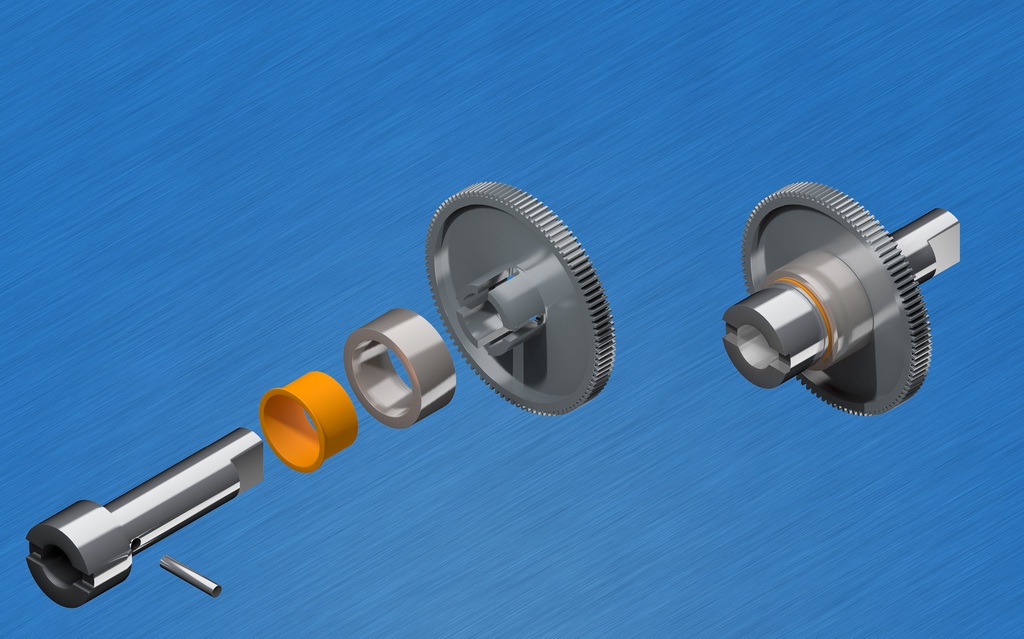

Plastic plain bearing specialist, igus UK, has launched a cost-effective manufacturing service – speedifit – to supply bespoke complete bearing assemblies.

A speedifit part is made by taking a standard or custom iglidur plain bearing, and fitting this into a bespoke housing machined to a customer’s drawing and specifications. Any igus bearing can be fitted into a housing which can be manufactured from many materials including aluminium, anodised aluminium, mild steel and stainless steel, titanium as well as common engineering plastics.

The customer sends the assembly and housing drawings directly to igus and receives a quote typically within 24h which includes fitting of all bearings. Once ordered, the speedifit manufacturing and assembly centre produces the custom part and the complete assembly is delivered ready to install, within the confirmed lead-time.

- Smart bearings help prevent machine failure

- Live webinar - Why should gears be 3D printed instead of machined?

- Protection For Extraction Hose

- igus acquires majority stake in Commonplace Robotics

- igus invests £4m in pioneering plastic recycling firm

- igus invests in automation

- Easy installation

- Lubrication-free linear guides for smooth operation

- Robotic energy supply system for dry cleanrooms

- Fast cable selection tool

- No related articles listed