|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Sensors | >Mini range expanded |

Editor's Pick

Mini range expanded

17 April 2015

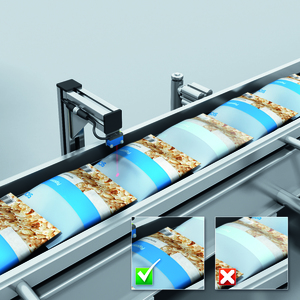

SICK is expanding it Mini range of registration sensors to provide reliable, high-speed contrast, colour and luminescence detection, following close co-operation with customers to meet even the most challenging packaging and production assembly needs.

The latest additions to the Sick Mini sensors are the KTM Prime Inox for hygienic environments, the CSM colour and LUTM luminescence detection sensors. Each has an excellent switching frequency and delivers high machine productivity for a wide range of matt and glossy materials.

"Each SICK Mini packs a mighty punch into a small sensor to be able to detect contrast, colour or luminescence reliably in even the most difficult circumstances,” explains David Hannaby, Sick’s product manager for presence detection. "The three-colour LED and smart ASIC onboard intelligence ensure that markings and colours will register despite being low contrast, badly printed or on reflective materials such as foils that dazzle less able sensors.”

With a housing measuring just 21mm x 12mm x 31.5mm, the Mini sensors can be mounted virtually anywhere. They are quick and easy to configure on the production line, with an onboard teach-in function for both static and dynamic modes. The IO-Link enables extended remote diagnostics and means format changes can be handled quickly and easily by retrieving the previous parameter settings from the control system’s memory.

"The sensors’ ability to see through reflected glare means that for the sensor set-up on the production line, the engineer does not have to fiddle with complex angles to minimise reflection while getting optimum signals,” adds Hannaby. "Even undulating surfaces or fluttering material can be accommodated.”

The registration Mini range is also expanding to incorporate the CSM for detection, checking and sorting of objects according to colour. The CSM offers a wide colour sensing spectrum and allows up to eight colours to be taught-in.

Where colour is used for mark detection, product checking or sorting, e.g. for work cycle synchronisation at bag forming, filling and sealing machines, the CSM offers wide colour sensing capability allowing up to eight colours to be taught-in.

With the same IP67 housing, the LUTM luminescence sensor can be relied on to detect fluorescent marks even when the luminescence factor is low and there is high glare. It is ideal for detecting non-visible registration and print marks and for label and packaging security applications.

The SICK KTM Prime Inox hygienic sensor delivers high-speed, reliable detection of contrast and alignment marks, even where there are low contrast levels or high gloss surfaces, suitable for a wide range of packaging, bottling and label printing applications.

With durable 316L IP67, or IP69 stainless steel housings, the KTM Prime Inox has a temperature range of between -30oC to +75oC. It is the ideal choice for hygienic pharma and food manufacturing applications where cold or hot processing conditions occur, or with hot wash down solutions.

The original SICK KTM contrast sensors are available in two models, the Core designed for base level applications with a single white LED signal emitter, while the KTM Prime, with three RBG LEDs, offers additional features.

All the new Mini registration sensors use SICK’s new ASIC (application sensitive integrated circuit) technology which has a much higher dynamic signal reception range. This capability prevents the sensor from being swamped by highly-reflected light and can also differentiate low contrast marks.

- Vision system delivers production gains

- Enables more effective human-robot collaboration

- Sensing innovations

- Ultrasonic sensors

- Out in all weathers - the quest for certifiable sensor safety outdoors

- Sensors get smart

- SICK unveils rapid changeover solution at TOTAL 2013

- Is it time to rethink 3D vision?

- Sick launches Safe EFI-pro System

- 2D LiDAR in the palm of your hand