|

Charlotte Stonestreet

Managing Editor |

| Home> | CONTROLS | >Flow Control | >Miniature valve |

Editor's Pick

Miniature valve

01 January 2016

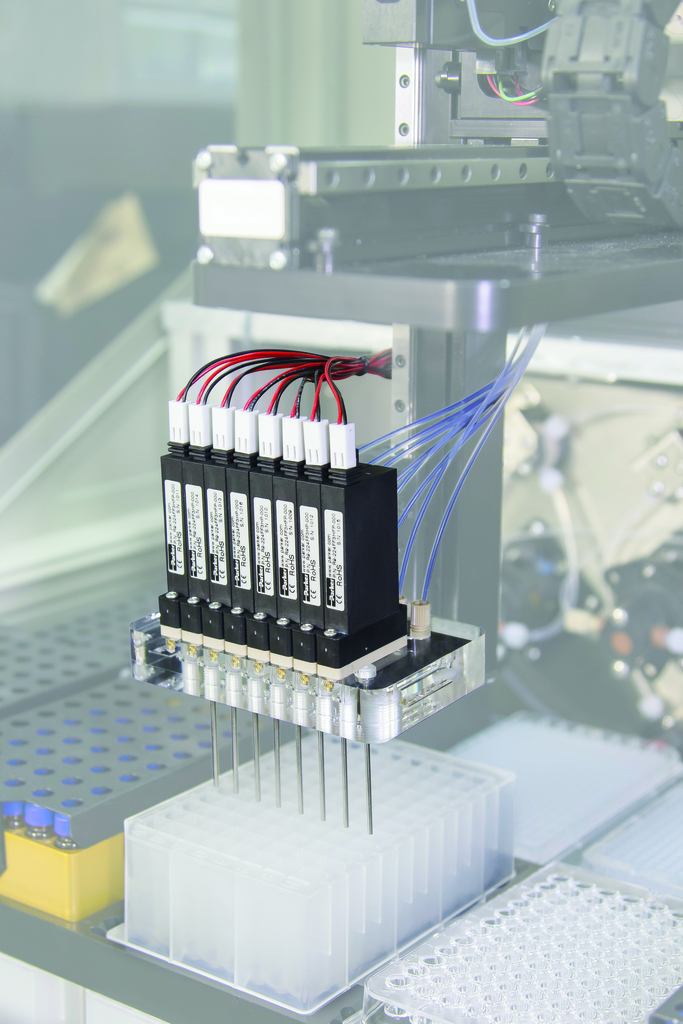

Parker’s R9 Diaphragm Rocker Isolation Valve family of ultra-compact (9mm) fluidic valves is designed to improve the performance of Clinical Diagnostic, Analytical Chemistry and Agent Detection systems requiring high precision fluid control.

Capable of delivering impressive liquid dispensing performance from a solution that measures just 9mm wide, the miniaturisation of the R9 valve means it can be mounted easily over micro plates to eliminate the requirement for transfer lines, improving performance and saving space.

This compact valve offers the flow typical of a 16mm valve in a 9mm width and typical applications include in-vitro diagnostics, hematology, molecular diagnostics, flow cytometry, genomics, proteomics, liquid handling, sample preparation, chromatography and high precision flow control.

The R9 has been developed in direct response to market requirements as OEMs in the life sciences sector make their fluidic systems smaller, while simultaneously increasing pressure ratings. When mounted on a manifold, the R9’s reduced footprint facilitates smaller and more efficient fluidic circuits by consuming less space and shortening fluid channels.

R9 valves also feature low carryover and low internal volume, with good particulate resistance. Capable of operating with a variety of flow and pressure ratings up to 6.8 bar, R9 valves support the use of smaller fluid passageways, reducing fluid consumption and increasing throughput.

The R9 Valve represents the latest in a series of recent additions to the Parker Precision Fluidic product range, and follows last year’s introduction of the Parker Smart Syringe Pump, which offers the highest performance/smallest package ratio available on the market. Earlier in 2014, Parker also unveiled its R6 diaphragm isolation valve, a 6.4mm valve that can also be mounted at the point of dispense.

With this expanded portfolio, Parker can provide the pumps and valves needed to meet the changing demands of today’s laboratory instrumentation sector, including sampling, reagent addition, wash, waste, and decontamination sub-systems.

- REGULATE FLOW

- FLOW CONTROL PRODUCT SEALS

- Verify Flow Controllers

- FUEL SAVINGS OF UP TO 30%

- ACCURATE POSITIONAL PERFORMANCE

- LARGE VALVE POSITIONER

- Fuel-cell race car relies on Bürkert valve technology

- Affordable Valve Management

- Multi-Finction Filtration Controller

- Air Flow & Pressure Switching Point Adjustment