|

Charlotte Stonestreet

Managing Editor |

| Home> | CONTROLS | >Linear | >LIVE WEBINAR: Sizing & selecting ball screw drives for standard & custom applications |

LIVE WEBINAR: Sizing & selecting ball screw drives for standard & custom applications

28 November 2016

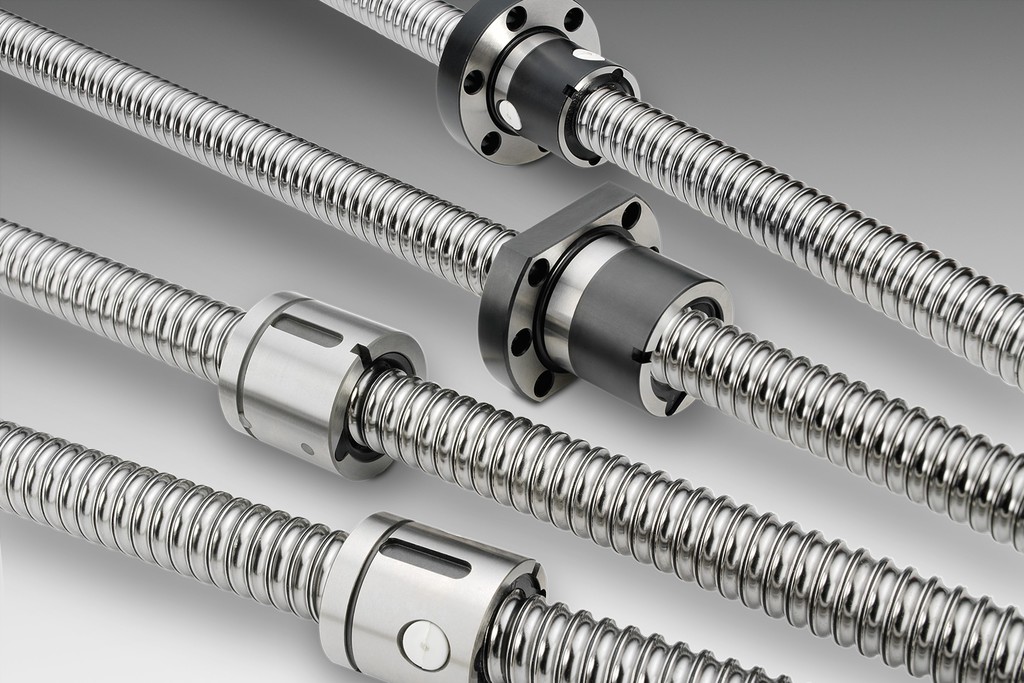

From all the thousands of possible choices on the market, how can OEMs quickly and confidently size and select the optimal ball screw solution for their linear motion application? Thomson Industries, Inc., a leading manufacturer of mechanical motion control solutions, is presenting a new webinar that will provide engineers with information to improve machine design with the optimal ball screw drive selection.

The selection of the correct ball screw assembly for a specific application is an iterative process that determines the smallest envelope and most cost-effective solution. The design load, linear velocity and positional accuracy are used to calculate the diameter, lead and load capacity of the ball screw assembly. Individual ball screw components are then selected based on life, dimensional constraints, mounting configuration and environmental conditions.

Thomson now offers a free webinar which will be held on 13 December, 2016 and it is aimed at giving a detailed technical insight to design engineers. It will be hosted by Jeff Johnson, Product Line Manager for Industrial Screws at Thomson Industries, who will talk about the necessary considerations, customization options and he will give a step-by-step guide in how to quickly and confidently size and select ball screw drives.

For further details, including how to register and dial in, please visit: http://info.thomsonlinear.com/acton/form/3484/0115:d-0004/0/-/-/-/-/index.htm

- Thomson introduces first collaborative 7th axis with collision detection

- Reconfiguring residential construction

- Off-highway actuator

- Upwardly mobile

- Raising the ergonomics bar

- High-load ball screw

- High power can come in small packages

- New White Paper: The Fundamental Benefits of Smart Actuators

- Thomson moves Swedish manufacturing to larger facility

- Bridging the performance gap