|

Charlotte Stonestreet

Managing Editor |

Editor's Pick

Size & select electric linear actuators online

11 June 2019

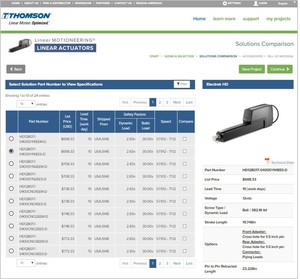

Thomson Industries has introduced a new Linear Motioneering online tool that helps design engineers accurately size and select electric linear actuators.

The powerful, self-service functionality of the tool provides an interactive series of questions, making it easier for users to benefit from Thomson’s extensive application engineering knowledge base. The online questionnaire starts with an analysis of motion control requirements, which leads quickly to an ideal actuator solution.

“Given the inherent design of our electric linear actuator products, it’s not uncommon for us to see misapplication in cases where a user attempts to select a product without the assistance of our applications engineering team,” said Håkan Persson, Product Line Director Thomson Linear Actuators. “Working from a spec sheet alone can get one close to the right match, but unless it is done within the context of a few fundamental application parameters, it is easy to end up with a costly mismatch. Our applications engineers are trained in an interview protocol that optimises selection and are readily available, but many designers still prefer to go on their own. We respect that desire and have created our Linear Motioneering tool to help them do that.”

The new selection tool guides users through the journey of sizing up an electric linear actuator solution to fit their application. It asks the same kinds of questions about mechanical, electrical and control requirements that a Thomson applications engineer would ask. Then, based on the responses entered, the Linear Motioneering tool returns the options that would best meet their requirements.

The following features help bring users to the right selection faster:

- Outcome-driven focus. The new tool guides users in clarifying application parameters up front for optimal selection.

- Broad range of feature options. The tool presents more options for voltage, stroke, control, adaptor location and custom connectors than users might otherwise find from searching on their own.

- Trade-off management. The tool presents results in a way that makes it easy to parse trade-offs among the options, revealing, for example, the impact of position feedback on cost or cost parameters on product life.

- Extensive help resources. As users proceed through the questionnaire, readily available help buttons provide additional information, tutorials and videos that help them clarify aspects of the questions. The help button in the environmental conditions section, for example, would lead to a tutorial on understanding ingress protection (IP) ratings.

- Off-highway actuator

- High load capacity

- Compact linear motion system

- Raising the ergonomics bar

- Marine-grade corrosion resistance

- Energy saving switch

- Linear unit sizing and selection tool upgrade

- Smart actuators help deliver Industry 4.0

- Energy efficient electric actuators on track

- Reconfiguring residential construction