|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Pumps | >Abrasive coatings pumped |

Abrasive coatings pumped

02 January 2017

Hydra-Cell seal-less pumps from Wanner have solved a pump seal wear problem for a major US producer of acoustic panels. When pumping abrasive coatings, pumps with dynamic seals eventually wear and leak. Performance accuracy deteriorates and maintenance downtime for seal replacement can prove expensive.

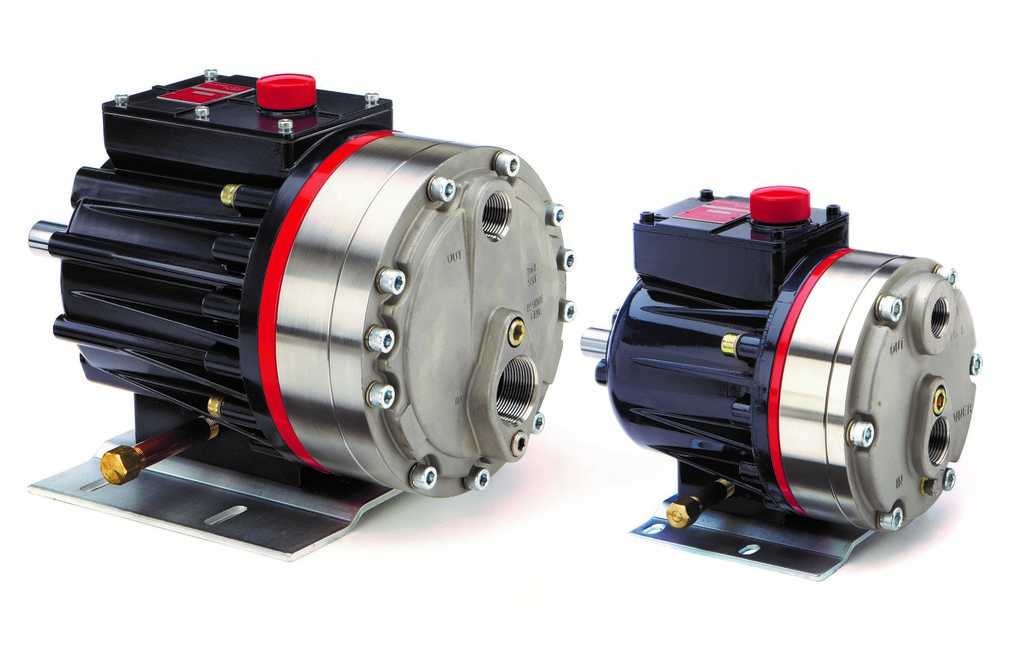

Replacing pneumatic, single plunger pumps with Hydra-Cell G10 and G25 seal-less pumps not only solved the leak problem but also greatly improved the control over spray patterns and coating thickness.

With no dynamic seals to wear, the Hydra-Cell pumps are able to pump the abrasive coating material reliably and require minimal maintenance, reducing non-productive time.

Having multiple, hydraulically balanced diaphragms in a single pump head, the Hydra-Cell pumps produce a smooth pulseless flow without the need for pulsation dampeners. The smooth flow also reduces pipe work stress in the system The controllable, repeatable delivery (±1%) ensures the spray pattern is regular and the coating is consistent over time.