|

Charlotte Stonestreet

Managing Editor |

Tape tension measurement

08 August 2018

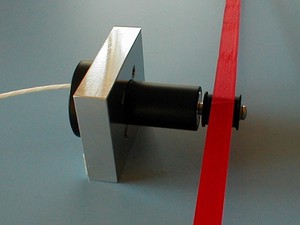

TTS Systems was recently asked to measure the tension in a 25mm wide tape as it was wound onto a specially shaped production mandrel. The process also required the applied tension to be varied as the component was wound.

The solution involved a custom designed roller with a standard transducer element and housing. The roller is 50mm wide, with a 38mm diameter at the outside edges and 37mm in the centre, this naturally pushes the tape to the middle of the roller. The design capacity was 25gg force. Using foil strain gauges in a full wheatstone bridge configuration, a nominal output of 0 to 20mV with a 10 VDC excitation can be achieved.

The output signal is processed using the DCA-10 loadcell amplifier, whilst a dual channel unit, it works just as well with only one measurement input. DIN rail mounted operating from a 24VDC power supply, the DCA-10 provides to two independent 0 to 10 VDC analogue outputs that can be used by the control system and a local digital display.

Speedy set up and calibration is always important, the DCA-10 has two push buttons and eight information LEDs. Zero calibration is done with no load on the transducer, with the push of a button. Then a known load is then applied to the transducer using a flexible load tape to hang a 25Kg weight on, the Span calibration is then completed. There is also an option to set the calibration data via the RS485 communications port, however in practice most engineers use the push buttons.

The calibrated high-level signal from the measurement system can now be used in one of two ways – with a dedicated tension controller designed to provide a simple local machine control solution or a PLC to offer greater programming and control capabilities. In this case our customer has a very good PLC engineer, who understands both their product’s construction and how to run the machine.

So, after a short commissioning period, the customer’s machine is now winding tape 15% faster than before and with the improved tension profile control during production the quality of the end product has increased.

- No related articles listed