|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Sensors | >Tape extension sensors |

Tape extension sensors

29 April 2015

Looking to extend and improve its already wide range of linear measurement sensors, ASM has taken the basic principal of a standard manual tape measure and re-engineered it to give an electronic output using a high specification stainless steel tape that is highly flexible. Integration of this to a re-wind spring arrangement and an ASM PRAM encoder results, says the company, in the operating principles of a new measuring device.

A similar principle has been used for many years using a plaited stainless steel wire winding over the circumference of a precision drum. More demanding industrial applications requiring higher duty cycles mean that in certain cases this is no longer suitable for the life expectancy of the process equipment.

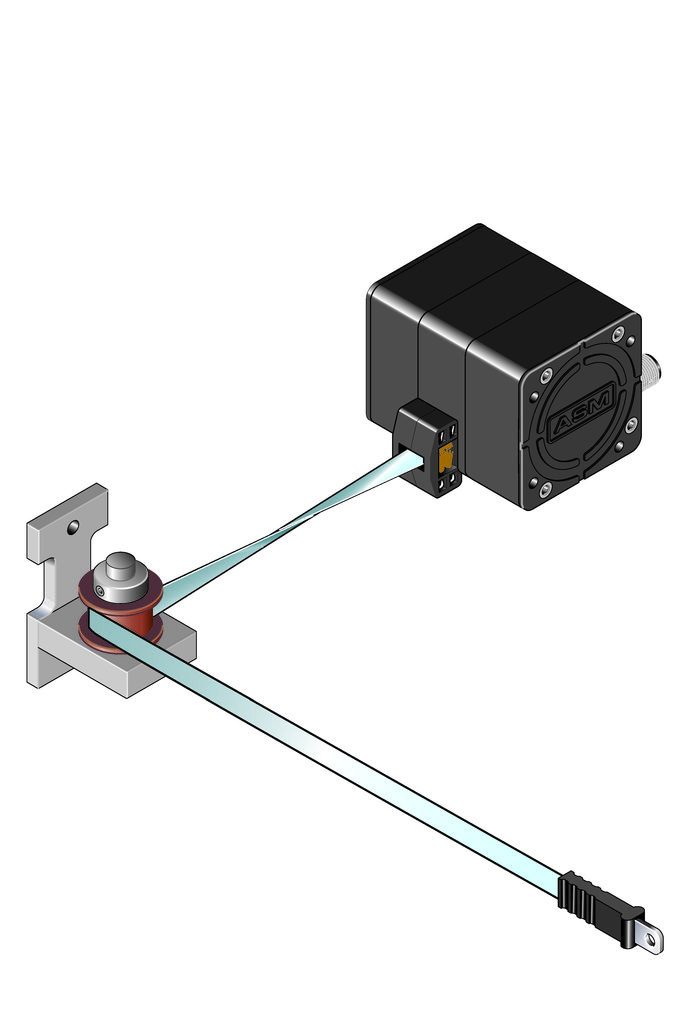

ASM has made significant improvements by utilising a 10mm wide and 0.08mm thick stainless steel tape. This is the core difference in the evolution of the Tape Sensor compared to a wire sensor. The life of the tape is unaffected when using multiple direction changing pulley’s for those difficult to reach places. In a wire sensor the life can be reduced by as much as 80% by using multiple pulley’s. The Tape Sensor gives the life requirement and reliability expected by today’s industries. Its flat smooth surface prevents ice build-up so it is also suited to harsher climates where mechanical devices are often prone to failure.

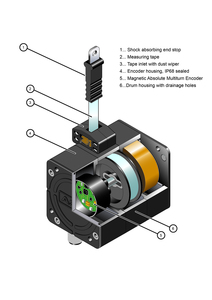

At the heart of the sensor is an ASM none-contact PRAM absolute, multi-turn encoder with on board signal conditioning. This is magnetically coupled to the drum arrangement which allows the tape to be over wound onto its self in continuous spiralling layer which is all kept under a constant tension with a tensator spring.

To attain the high positional accuracy required the sensor is only programmed and linearised after assembly. This is due to the over winding of the tape which would otherwise not give a linear output. This new improved system enables us to offer a standard linearity of 0.10%. Optionally a higher linearity of 0.05% is also available all in a wide range of compact housings.

The main failure mode of conventional ‘contacting’ position sensors is that they wear out much more quickly than ‘non-contacting’ systems. By using the ASM PRAM non-contact Magnetic Encoder the performance is immediately improved compared to systems using potentiometers or other contacting technologies. The performance of the stainless steel tape enables the operating life expectancy of the sensor to be unaffected especially when incorporating directional changing pulleys.

Also due to the overwind design of the internal tape pulley if the sensor is accelerated beyond its specification then the tape is unable to ‘jump off’ the pulley as is sometimes the case with a ‘wire draw’ system.

The new PRAM sensing element electronics are fully encapsulated enabling them to work in much harsher environments where shock and vibration as well as dust, grease and condensation may have caused previous concerns. For safety critical areas devices can also be offered with a redundant output which can be used as an independent output or for error checking and failure of supply voltage

A wide range of both analogue and digital absolute outputs are available including CAN bus options to meet today's varied requirements.

- No related articles listed