|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Pumps | >Pumps with Tri-Clamp fittings |

Pumps with Tri-Clamp fittings

16 June 2015

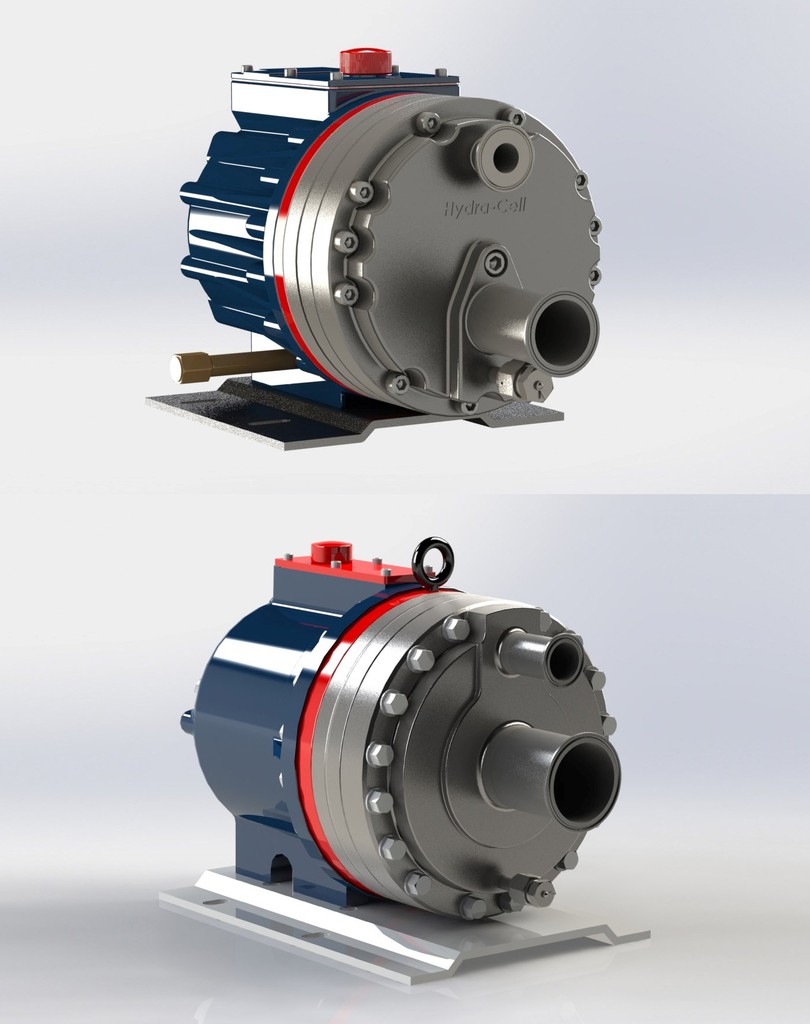

Wanner International has added Hydra-Cell G25 and G35 pumps to its list of models available in 316L stainless steel, with Tri-Clamp ferrules and polished internals, for sanitary applications.

Tri-Clamp fittings are easy to assemble and breakdown, making them suitable for short term process lines and equipment. Used extensively in food, drink and pharmaceutical processing, their smooth crevice and pit free interiors offer non-contaminating, superior corrosion resistance and long service life.

In order to meet clean-ability requirements these Hydra-Cell pumps have completely new manifolds with redesigned galleries that allow access for polishing to a certified surface finish.

All wetted parts (Tri-Clamp ferrules, manifold, valve plate, valves, valve seat, springs, retainers) are polished to either Ra 0.4 or 0.8 µm and come with TSE, Passivation, & Weld Procedure certificates as standard.

Designed for the transfer, metering, dosing and spraying of a wide range of materials, including those that are abrasive, viscous or shear sensitive, Hydra-Cell pumps are completely enclosed units with no bearings or rotary seals to come into contact with the product stream.

As threaded connections are not considered acceptable in these applications, drain ports, using Swagelok VCR components, have also been included.

These pumps are true positive displacement pumps, and meet or exceed API 675 metering performance requirements in terms of accuracy, linearity and repeatability.