|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Robots | >Direct drive robotic arms |

Editor's Pick

Direct drive robotic arms

16 June 2015

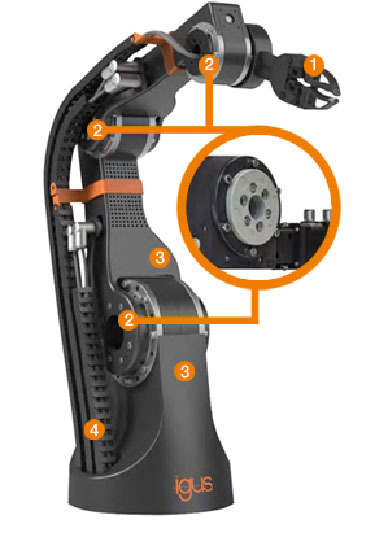

New from igus is the next generation robolink D; a direct drive joint kit that is available in three different sizes and can be combined to form customised and configurable 1- to 4-axis articulated robotic arms.

Robolink D is intended for robot manufacturers, mechanical engineers and automation specialists, working in a variety of industries ranging from automotive production to medical technology.

Each low-cost joint kit comprises a PRT polymer slewing ring bearing, which is self-lubricating and therefore maintenance free, and worm gear, which is housed in plastic for added protection while ensuring weight is kept to a minimum.

For direct drive of the joint, a NEMA motor with the appropriate cables can be integrated in the axis and equipped with an encoder to send angle signals back to the controller. A variety of different grippers is available optionally.

Both the individual components and the pre-assembled system with construction diagrams are readily available. A fully-assembled robolink D system is available on request.

- Heavy duty linear guides

- Wimbledon's roof glides with energy chains

- igus invests in automation

- Lighter linear guide

- CABLE STRIPPING IN HALF THE TIME

- Low-priced delta robot

- igus makes e-chain recycling even easier

- Latest additions to linear guide system

- 36-month guarantee for igus e-chains

- Compact design solutions

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- NUMBER OF ROBOTS IN UK ON THE RISE

- The future is bright - The future is automation!

- High Demand For Grant

- More Capacity, Less Space

- FREEBIRD - THE THIRD DIMENSION

- PRECISION ROBOT CELL FOR THE PHARMACEUTICAL INDUSTRY

- ROBOT SALES REACH ALL TIME HIGH