|

Charlotte Stonestreet

Managing Editor |

High speed industrial automation

15 July 2016

For automation applications calling for high sensitivity, fast integration and super accurate camera synchronisation and triggering, FLIR Systems introduce fixed mounted A66xx-Series for automated thermal inspection and process control on high speed production and processing lines.

FLIR A66xx thermal imaging cameras have a cooled Indium Antimonide (InSb) detector making them the most sensitive in the standard FLIR A-Series range - able to see minute temperature differences, capture high-speed thermal events and measure temperatures of very small targets.

The InSb cyrocooler allows the FLIR A66xx to operate in the 3 to 5 micron, mid-wave infrared band where thermal contrast is high making it easier to detect objects against a background that offers little thermal difference.

A global shutter adds to the camera's ability to inspect fast moving objects allowing the output of all pixels to be read simultaneously: suitable for applications with high line speeds such as paper manufacturing.

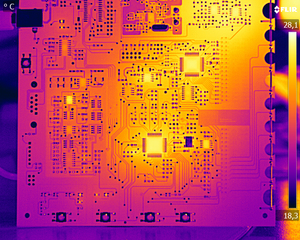

FLIR A66xx models offer greater magnification capacity. Increased sensitivity means that lenses with more optical or thicker elements are used without degrading the signal-to-noise ratio: ideal for the dynamic thermal checking of electronic circuit boards.

Cameras may be specified with custom cold filtering options for specific spectral detection and measurement, allowing these models to image through glass, measure the temperature of thin film plastics and filter different wavebands for laser profiling and detection.

FLIR A66xx cameras use a standard GigEVision™/GeniCam interface to transmit both commands and full dynamic range digital video. A software developer’s kit is also optionally available with both models.

Full details of the FLIR range of automation cameras can be found here: www.flir.co.uk/automation/display/?id=70605

- Critical equipment monitoring

- High-speed thermal imaging camera

- Imaging in all its forms

- Intelligent choice for real-time application

- Thermal imaging clamp meter

- Locates smaller compressed air leaks

- Understand the bigger picture

- Run camera-guided inspections with the FLIR T865

- FLIR completes strategic investment in DroneBase

- FLIR receives Red Dot

- No related articles listed