|

Charlotte Stonestreet

Managing Editor |

Editor's Pick

Open software platform

03 April 2017

The recenty launched Sick AppSpace is an open software platform for programmable sensors that system integrators and Original Equipment Manufacturers (OEMs) can use to develop and implement tailor-made application solutions on Sick programmable devices.

Hailed as an exciting new “eco-system” for bespoke application development, SickAppSpace gives users unprecedented flexibility to exploit Sick’s growing range of smart vision systems and intelligent sensors.

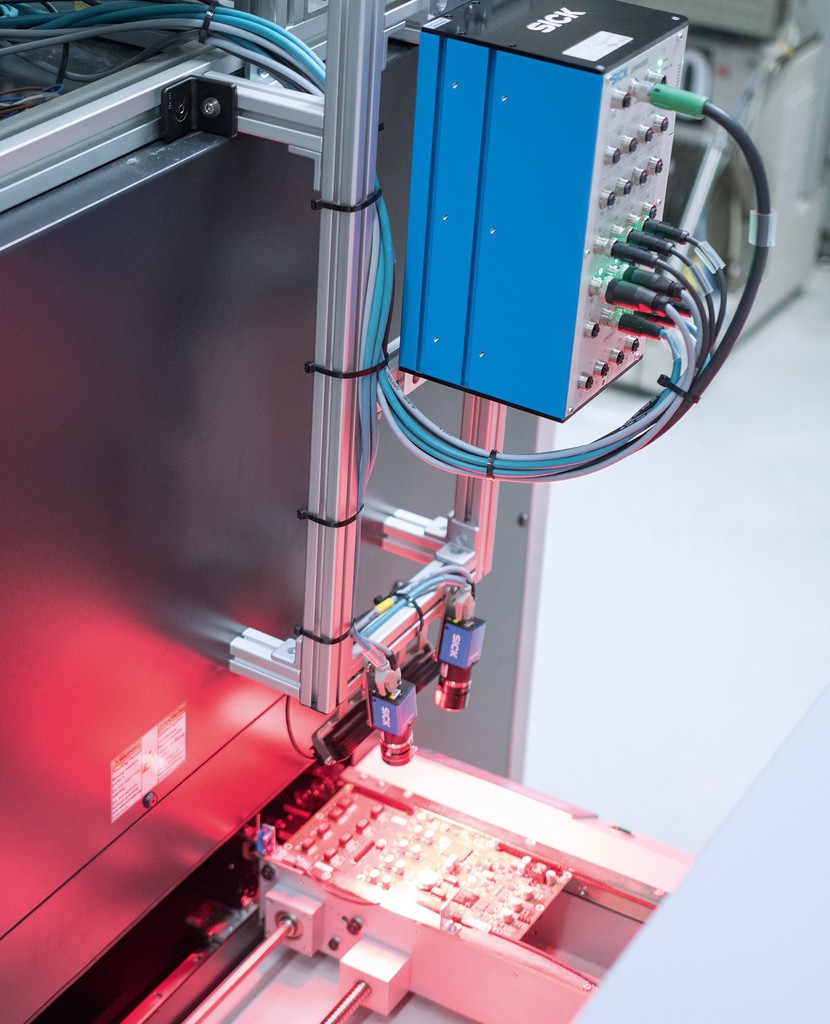

Sick AppSpace is supported by the new Sick SIM4000 Sensor Integration Machine, a high-performance, one-box, multi-core processor that can integrate multiple cameras and sensors together with powerful image processing.

The SIM4000 offers up to 25 interfaces for Ethernet-based fieldbuses, cameras, illumination, sensors and encoders. Its functionality includes 10-gigabit Ethernet interfaces for 2D or 3D cameras, and in some cases features a voltage supply over Ethernet (PoE). Sensors including RFID and laser scanners can also be integrated via IO-Link for distance and height measuring purposes.

Data from Sick sensors and vision devices can be merged into a point cloud, evaluated, archived, and transmitted via the SIM4000. It can be used in factory and logistics automation for multi-sensor or camera-based inspection for measurement and identification, as well as for data acquisition, archiving for quality control, process analysis or predictive maintenance.

User-specific requirements

Says Neil Sandhu, Sick’s National Product Manager for Imaging, Measurement, Ranging & Systems: “Sick AppSpace is all about integrating hardware and software to achieve user-specific requirements efficiently through made-to-measure sensor apps. Sick’s programmable sensors, such as the new Inspector P family of programmable 2D vision cameras provide the foundation. The SIM4000 Sensor Integration Machine then enables multiple device image processing and data collection, where needed.

“Meanwhile, on the software side, the solution encompasses the Sick AppStudio for application development and the Sick AppManager for implementing and managing apps in the field. The Sick AppSpace Developers Club forms the final part of the concept. This is a growing community where developers from Sick and our customers can exchange information and ideas.”

Development freedom

With Sick AppSpace, developers have the freedom to design, develop and deploy their own customised solutions, perfect easy-to-use web-based graphical user interfaces for operators and distribute their applications across multiple hardware platforms and locations.

Developers have access to industry-standard image processing libraries including HALCON. They can work with their preferred programming technologies including graphical flow Editor, the widely used and powerful Lua scripting tools as well as C++ or Java. There are many integrated support functions such as auto completion, so that programmable sensor app developments will insert themselves easily into existing development processes.

Helpful utilities such as emulators, debuggers, resource monitors, and an extensive range of documentation and demo apps also make the development process easy. All software components are combined by the PackageBuilder into a single package that safely defines access rights.

“Sick AppSpace opens up amazing potential for specifically-crafted application solutions and for integrating multi-sensor data input,” concludes Sandhu. “In the Industry 4.0 organisation, whatever the application, global connectivity will be complemented by very specific individual and localised solutions with distributed, decentralised intelligent hardware and software integration. The Sick AppSpace eco-system will be the creative platform that supports this development for Sick customers for many the years to come.”

- Hand-held CANopener

- 3D vision made easy for all

- Ten second sensor change

- Flat out for sub-miniature performance

- Compressed air energy monitoring

- Open protocol interface

- SICK's advanced IO-Link encoders streamline machine controls

- 2D quality inspection

- SICK Goes the Distance with its Miniature PowerProxR Sensor

- Ultrasonic sensors

- No related articles listed