|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Connectors | >Production process savings |

Editor's Pick

Production process savings

16 November 2017

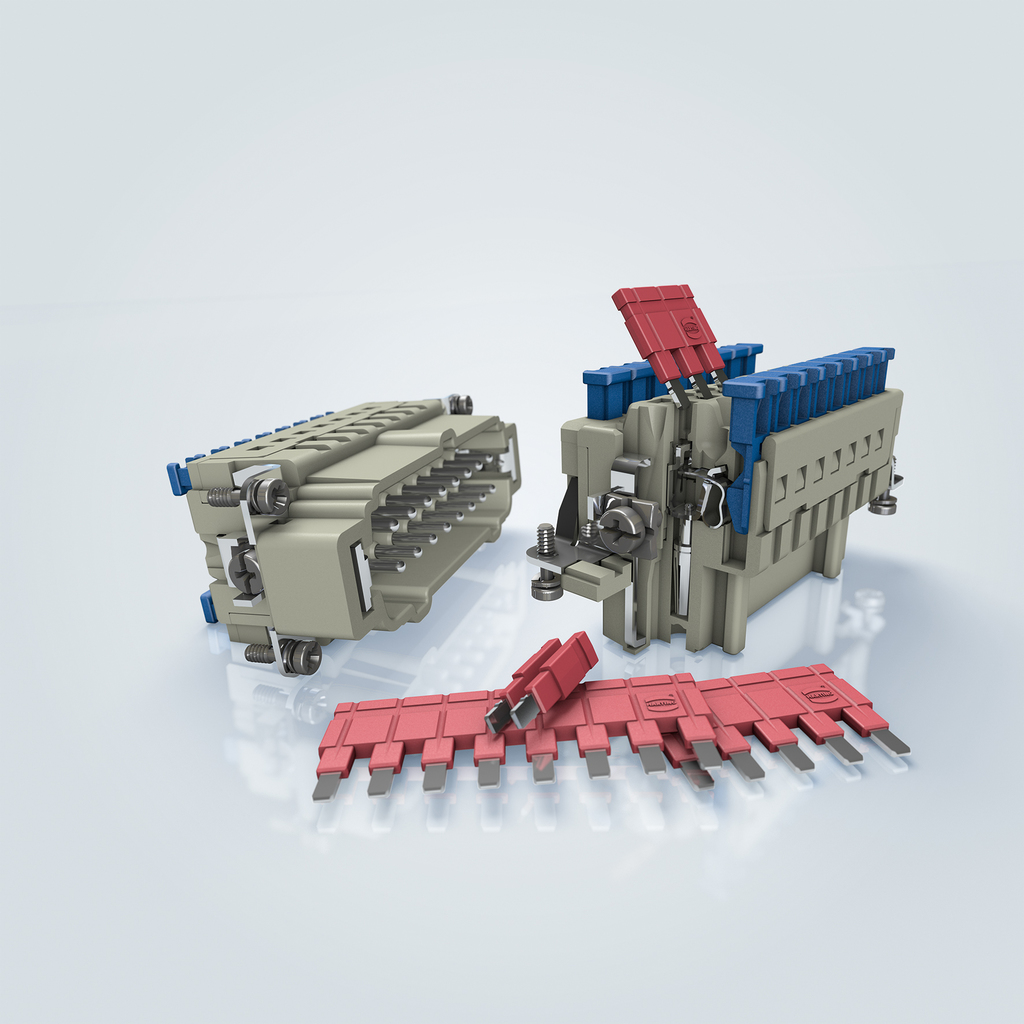

Offering fast tool-less termination based on an innovative high-reliability cage-clamp design, Harting’s Han ES Press connector is playing a key part in minimising installation time for motorised safety roller shutter door guard systems for the robotic assembly cells in an automotive assembly line.

“In today’s automotive plant installations, it is becoming more and more important that functional line control equipment is installed and maintained as easily and quickly as possible to minimise downtime”, says Howard Forryan, product marketing specialist at Harting: “This installation is a classic example of how advanced component designs can enable operational features that are critical for all sections of the full supply chain of OEM, systems integrator and automotive plant manufacturer.”

The door guard systems ensure the safety of workstation operators through integrated light curtains that detect and prevent personnel being present in a functioning robot work zone, and the manufacturer of the machine guards has chosen the Harting connectors – which are approved for use in automotive production environments - for the key input and output power and control circuits to the 415 V brake motors that drive the roller doors.

The manufacturer’s key reason for choosing Harting was that the termination features of the Han ES Press connectors allow rapid assembly within the control panel and correspondingly simple line cabling installation for the systems integrator and installer.

The Han ES Press’s cage clamp is supplied in an open state, so that a pre-stripped wire conductor can be inserted directly and without effort at the rear. A movable plastic plunger is integrated into the insert to close the cage-clamp chamber for guaranteed electrical termination of the wire conductor. The plunger can also be very quickly released with a screwdriver lever if a wire has to be removed for maintenance purposes.

An assembly time saving of as much as 50% can be achieved by using this intuitive cable termination technique over alternatives such as screw or crimp connection.

The Han ES Press connector also allows certain contacts within the connector to be commoned or bridged together through jumper links that are plugged into the rear of the connector insert. These jumpers are available in a range of pin configurations and in different colours to suit different wiring configurations such as 24 V DC or neutral connections. Such functionality can be very useful in automotive production line situations where certain key equipment is wired together in a “daisy chain” configuration. In such cases, it can be important that the last unit sends a “closed/made” circuit signal back to the control equipment to indicate that the circuit is complete. A two-way Han ES Press bridge link enables the two required pins to be connected with one another to give the necessary feedback signal.

The Han ES Press rear contact bridging link design feature can also help in the commissioning of production line machinery and robot cells. For example, if line maintenance or installation engineers need to short out the E-stop circuit, the Han® ES Press bridge link can be used to replicate the closed circuit. Similarly, if the coil circuit on a motor circuit needs to be completed to energise the contactors, two dedicated pins can be linked across to one another.

- For harsh environments

- For potentially explosive areas

- What is Integrated Industry?

- Signal Integrity

- Integration with high mating cycle connectors

- New webinar series from Harting

- Quick connect connectors

- HARTING to showcase modular solutions at Smart Factory Expo 2020

- Harting - shaping the future for 75 years

- Rapid assembly connectors