|

Charlotte Stonestreet

Managing Editor |

Editor's Pick

Expansion of drum motor platform & conveying solutions

07 August 2018

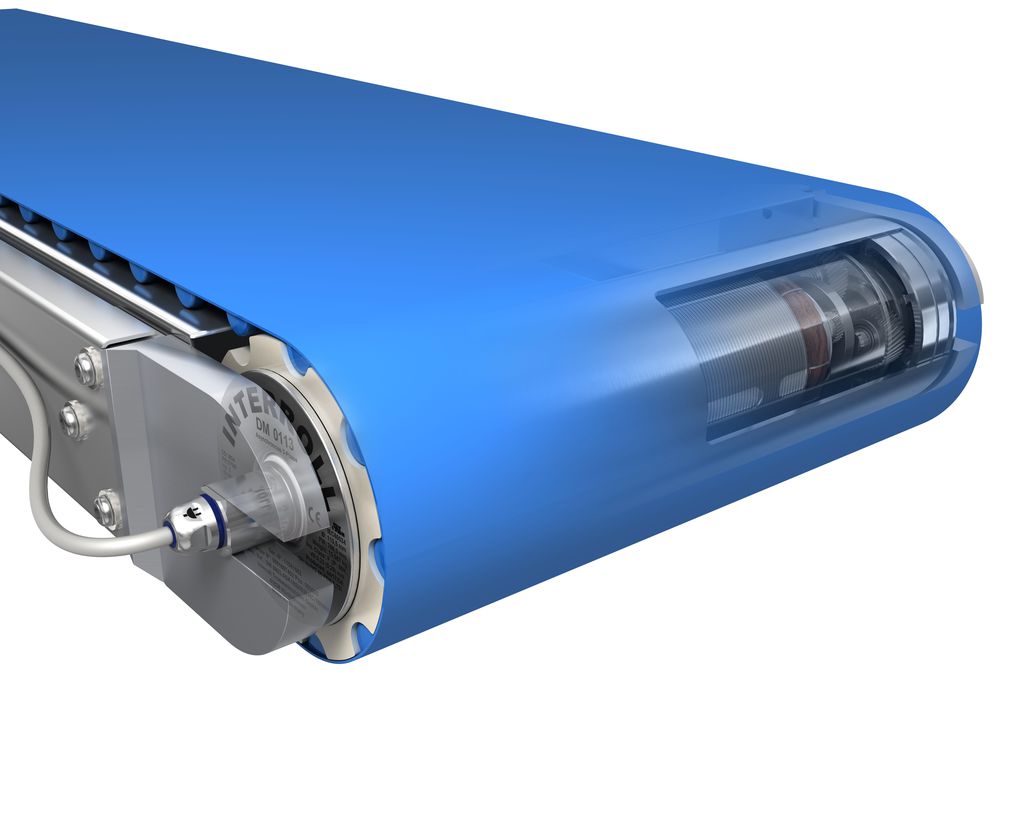

At PPMA 2018 Interroll will highlight the expansion of the new modular designed drum motor platform from 80mm diameter drums, to include the new DM0113 & DM0138, all available with an asynchronous or synchronous motor winding. Predominately used in belt conveyor applications, each motor is tested and designed in modular fashion to support shortest delivery times.

Stronger shafts and ball bearings ensure extra-long lifespan and the extremely stable design with a planetary gearbox allows higher torque to be transferred with low levels of operating noise. All the hygienic drum motors comply with IP69K.

Energy efficient 24V drive technology

Interroll will display the 24V EC310 RollerDrive that makes it possible to build-up an intelligently controlled conveyor system divided into zones. The drives of each individual conveyor section are only powered when material is actually conveyed.

At throughput rates of 600 to 1800 units per hour, this achieves energy savings of up to 50% in comparison with continuously running motors. Stand F10

- Modular conveyor platform

- Interroll cancels appearance at LogiMAT

- New Smart Pallet Mover from Interroll

- Interroll raises profile

- Fully automated material flow

- High-performance crossbelt sorter

- Interroll establishes new service organisation

- Performance boost for manufacturing logistics

- Motorised drive solutions

- Modular solutions for automated pallet conveyance

- No related articles listed