|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Connectors | >Connecting to industrial transformation |

Editor's Pick

Connecting to industrial transformation

19 December 2022

Harting Technology Group's Han connectors have been supplying machinery, manufacturing and other industries with the three lifelines of data, signals and power since 1956. Mark Rushdon looks at how consistent connector innovation has helped customers keep pace with industrial transformation

HARTING FOUNDER Wilhelm Harting was quick to recognise that industrial expansion in the post-war era would drive a demand for technical products. In collaboration with technical experts, he was able to develop a connector that would be robust, easy to handle and suitable for a variety of purposes.

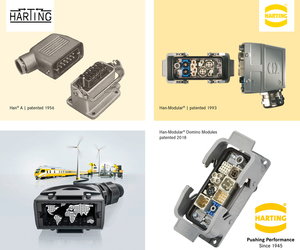

By the early 1950s, the Han (meaning Harting Norm) connector had made its debut. It was patented in 1956 and officially registered as a trademark in 1957. Into the 1960s, the production of Han had increased to encompass products for various voltages and currents, meaning all areas of industrial application could be catered for.

Over the following decades, the Han range continued to expand alongside the demands of industry, ensuring customers had the correct solution for their needs. Some notable developments include Han HP, designed to be corrosion-resistant with high IP ratings, thus meeting the higher requirements for tough environmental conditions. This was followed by Han HPR, a new solution for the rail market, which offered larger housings to handle increased cable diameters and improved EMC performance.

Increasing modularisation

In 1993, Harting launched Han-Modular, a direct response to the increasing modularisation of mechanical engineering. This innovation allowed contacts for the transmission of different media, such as data, signals, power and compressed air, to be placed side by side in a housing with the aid of a mounting frame. This meant customers could optimally design solutions for the supply of machines and systems using connector housings in standard sizes. With over a hundred different inserts, Han-Modular ensured a wide range of customisable options.

Harting also launched the Han Configurator, an online 3D tool which lets designers build a modular connector. The smart assistant feature suggests alternative interfaces and provides an onscreen 3D visualisation of the current configuration, meaning customers can view their creation from a range of angles. It’s also extremely easy to download all documentation (including STP files) and share configurations within a team.

In 2020, new customising functions were added to the Han Configurator. Users can now define the number, size and position of cable entries and apply individual laser markings to identify cables and equipment.

The development of Han-Modular was crucial, as it improved the flexibility of the range, opening up applications and opportunities in new markets. For example, the increased contact density and option for signal and power transmission made it perfect for robot controller cabling, whilst the modular aspect was ideal for wind turbines, as their components are manufactured in different locations before they are joined together on site. Han-Modular is currently used in generators, pitch control systems and in wind tracking, as well as transmitting power, data and signals from the nacelle to the rotor hub.

Shock resistant

Manufactured in their Northampton production facility, jumper cables for rail vehicles run connections between train carriages via roof or underfloor systems. These must be fully resistant to shocks and vibrations while transmitting data and signals securely. Also, as the demand for data communications in rail vehicles increases, powerful network and data interfaces are required to power information systems and fast, reliable internet access.

The Han Gigabit module enables Cat. 7A transmission in the inter-vehicle area and delivers higher frequency bandwidth for the flow of data. It is also shock and vibration resistant according to EN 61373. With new innovations such as the Han M12 module for Cat.5E and Cat.6A (D- or X-coded), Harting is looking to set the future standards for industrial interfaces in rail vehicle construction.

Almost 30 years on from the launch of Han-Modular, the next development stage of the modular connector is upon us with the new Han-Modular Domino range, which offers significant improvements for machine building thanks to space savings of up to 50%, compared to existing designs.

Just as dominoes have two separate squares, a domino module is made up of two building blocks or ‘cubes’. The Han-Modular mating face is divided in two, resulting in an almost square surface in which even larger contacts can be accommodated. These cubes allow users to configure customised connectors which are exactly tailored to their design requirements. Power, signal, data or compressed air can now be combined in one module, reducing the total number of interfaces required.

Also, as the connection technology becomes smaller and more lightweight, users can now fit more modules and module types than before into one connector. As a result, assembly areas which are difficult to reach can be equipped more efficiently or even opened up for assembly in the first place.

Design flexibility

With the addition of the new Domino range there are now over 250 modules to choose from and many thousands of potential combinations available, increasing design flexibility. The new Domino modules are also compatible with standard components of the Han-Modular series so they can be easily integrated into existing systems and machinery.

That brings us up to date with the Han story so far, but as the Harting slogan ‘Pushing Performance’ suggests, the ongoing challenge is to constantly innovate and help push developments further.

Rapid technological advances such as the digitalisation of industry and the changing requirements of customers and partners have led to the strategy of Connectivity+, a future vision for products and applications.

Product development will be driven by the societal megatrends of sustainability, (de)globalisation and demographic change. These in turn will influence technological changes, such as modularity, autonomy and the digital twin.

The Connectivity+ strategy will have the customer at its heart. For example, an extensive product portfolio has its benefits but can also create complexity. By expanding their digital offering, Harting will offer customers a wealth of online options, including watch lists, product documentation and engineering data.

The Han Configurator will also be improved so even single-item batches (‘batch size 1’) will be possible. All the configuration data will be automatically saved in the system with its own article number and corresponding documentation, simplifying the repeat order process.

In addition, Connectivity + aims to make workflows and process reliability more efficient, improve sampling for quicker prototypes and combine physical and digital components with the aim of improving the design in process and product production.

Mark Rushdon is UK marketing manager at Harting UK

Key Points

- Debuted in the 1950s, the Han connector was designed to be robust, easy to handle and suitable for a variety of purposes

- The Han-Modular was developed as a direct response to the increasing modularisation of mechanical engineering

- The new Han-Modular Domino offers significant space savings of up to 50%, compared to existing designs

- Optimised for industrial environments

- More power for system devices

- Connectivity for future technologies

- One trillion combinations possible

- Signal Integrity

- IIoT & virtualisation whitepapers

- MANAGEABLE NETWORK CREATION

- Harting - shaping the future for 75 years

- Power connection directly onto the PCB

- Miniature connectors