|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Handling & Logistics | >Cost effective pick & place |

| Home> | AUTOMATION | >Robots | >Cost effective pick & place |

Cost effective pick & place

01 July 2013

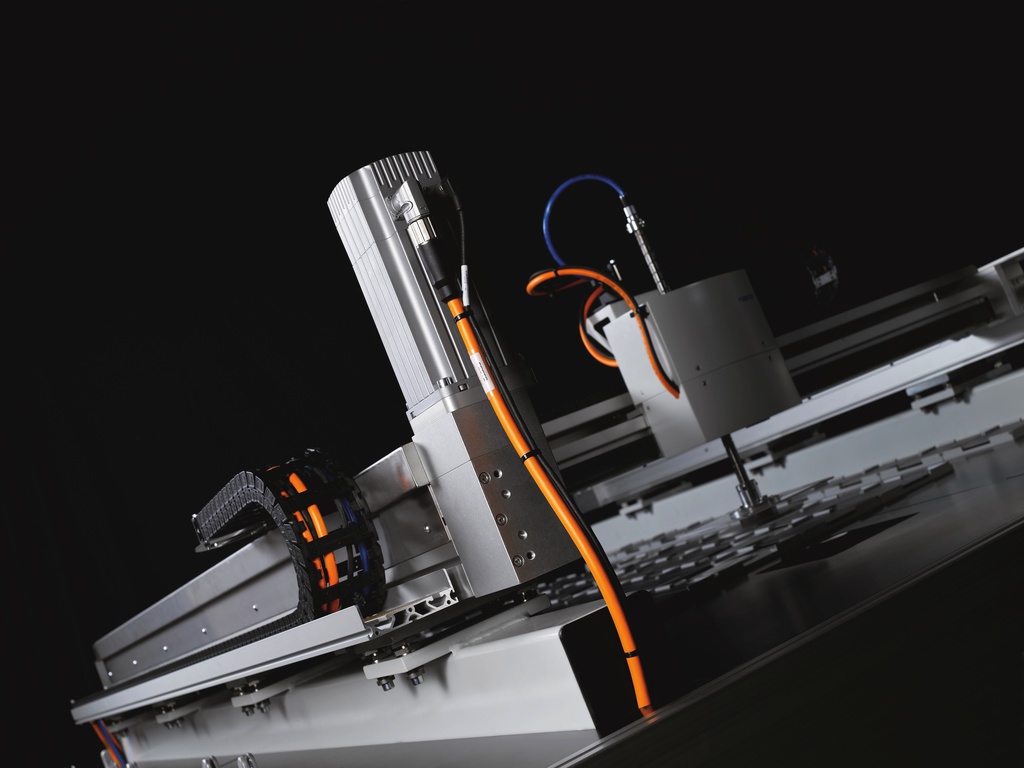

Manufacturer and systems integrator of pick and place solutions, Pacepacker Services, has expanded its product portfolio to include Festo’s range of Mechatronics pick and place systems.

Unlike most other mechanical pick and place solutions, which tend to be highly bespoke and custom built, the Mechatronics ‘off the shelf’ range offers quick and cost effective pick and place components.

Pacepacker is an integrator for a number of leading robotic equipment manufacturers, enabling it to offer an extensive portfolio of solutions to meet all project specifications.

Applications usually range from one to six axes with pick-up devices for handling one or multiple products at a time (complete or part layers). Typical uses include projects in the food, bottling, FMCG and pet food sectors.

The Mechatronics range comprises tried and tested pneumatic, electrical, mechanical, control and sensory components, models and systems which can be easily configured to provide pick and place solutions, tailored to the end user. Typical life expectancies are in excess of 5 million metres of travel.

- More bags for your buck

- Automation awareness workshops

- New-generation robotic palletiser

- Vertical tray packing solved

- LOCAL MP LAUNCHES ROBOTIC PACKING INNOVATIONS

- Automation for the people

- Resist the impulse to blame the robots

- Pacepacker extends portfolio with Festo Mechatronics

- Versatile robot packing solutions

- Pick & place robots

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- FIRST FASTBOX

- NUMBER OF ROBOTS IN UK ON THE RISE

- Tailor Made For Automated Warehouses

- Number of Operators Reduced

- Prevents Potential Material Release

- Integrated or Standalone

- The future is bright - The future is automation!