|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Robots | >Automation for the people |

Automation for the people

18 July 2016

Having experienced a 40% rise in industry robotic enquires in the last 12-months, managing director of Pacepacker Services Dennis Allison believes the growth in smart machines and automation will actually be a catalyst for new and more exciting knowledge-based jobs in the future

It’s a fact of life; mundane tasks are not something people passionately relish. Yet, the fear of job losses due to automation continues to unsettle workers in the manufacturing sector.

“When reports are released it creates an element of scaremongering among the workforce,” notes Dennis. “The fact is, robots and smart technologies are filtering into every work environment. For the manufacturing sector, rather than dehumanising people, many of the tools today can free workers from the labour intensive and mundane tasks, enabling them to focus on more creative aspects of their job, like problem solving.”

According to the most recent research into automation adoption prepared by the International Federation of Robotics (IFR), two million jobs will be created by 2020 because of the robotics industry. What’s more, a further 60,000-80,000 new activity jobs will be created in the food industry alone by 2016*. “Our study proves that robots create jobs," said Gudrun Litzenberger, General Secretary of IFR. "Productivity and competiveness are indispensable for a manufacturing enterprise to be successful on the global market. Robotics and automation are the solution. Certain jobs may be reduced by robotics and automation. But the study highlights that consequently many more jobs are created."

This opinion is echoed by the labour market intelligence published in the UKCES Advanced Manufacturing Sector Insights report**, which suggests that manufacturing in the future is going to be heavily influenced by advanced technologies. Dennis puts this into context. “In response to changing customer demands we’re already seeing a shift in shorter production runs and more personalised products. What’s more, a number of food suppliers sub-contract the packing aspect of the supply chain. This is creating greater demand for people with more specialist technical and project management skills coupled with broader science and engineering capabilities.”

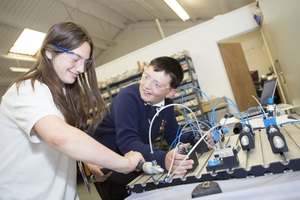

In light of these skills, Dennis is reassured that there appears to be plenty of existing and fresh talent to fill these job roles, saying that automation is a hot ticket right now for career advancement. Through community activities, Pacepacker is observing a surge of interest among young people eager to get into robotics, programming and research and development.

Last summer the company hosted an open day for two local secondary schools. Throughout the day the students were encouraged to explore the ladders of opportunity and encouraged to get hands on with some of the newest technology “Everything starts with an idea and STEM subjects are used throughout the entire process, from design through to installation. It is always a pleasure to see how inquisitive these young students’ minds are and how fast their skills are developing,” says Dennis. The company also joined the Chelmsford Engineering and Innovation Community in late 2014 and teamed up with Anglia Ruskin University to offer graduate workshops and industrial placements.

Rather than people’s jobs being displaced, Dennis believes that these machines can help enrich people’s lives and create greater job satisfaction. People whose positions become redundant due to automation are invariably given roles elsewhere within the business, he claims. “Automation is often referred to as AI - artificial intelligence. I would argue that automation still requires personal input and numerous human attributes like problem solving. That means it isn’t artificial, but natural progression.”

Although there might be fewer jobs on the production line, automation will help manufacturing business models to evolve faster, increasing their chance of survival, points out Dennis. “It’s a tough time for manufacturers right now. Many are competing harder on price and business costs are being further compounded by recent policy announcements like the national living wage, new pension arrangements and the introduction of the apprenticeship levy. Enterprises of all sizes are realising that they can take labour out of their costs and redeploy it elsewhere if they automate. In our view, automation safeguards the roles of the majority, making the business more efficient and enabling it to maintain and hopefully expand its contracts by improved quality and production throughput.”

Summing up, Dennis says: “Work should be a source of inspiration and happier employees equate to more productive employees. If automation can assist businesses to survive, increase productivity and create greater human fulfilment, everyone benefits.”

- Cost effective Cartesian

- LOCAL MP LAUNCHES ROBOTIC PACKING INNOVATIONS

- Mixed product trays

- Cost effective pick & place

- Pacepacker extends portfolio with Festo Mechatronics

- Vertical tray packing solved

- Resist the impulse to blame the robots

- Easily programmed robotic palletising

- The food factory cobots are coming … or are they?

- Diagnostics from a distance

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- NUMBER OF ROBOTS IN UK ON THE RISE

- The future is bright - The future is automation!

- High Demand For Grant

- More Capacity, Less Space

- FREEBIRD - THE THIRD DIMENSION

- PRECISION ROBOT CELL FOR THE PHARMACEUTICAL INDUSTRY

- ROBOT SALES REACH ALL TIME HIGH