|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Handling & Logistics | >Automated engine transfer |

Editor's Pick

Automated engine transfer

10 June 2014

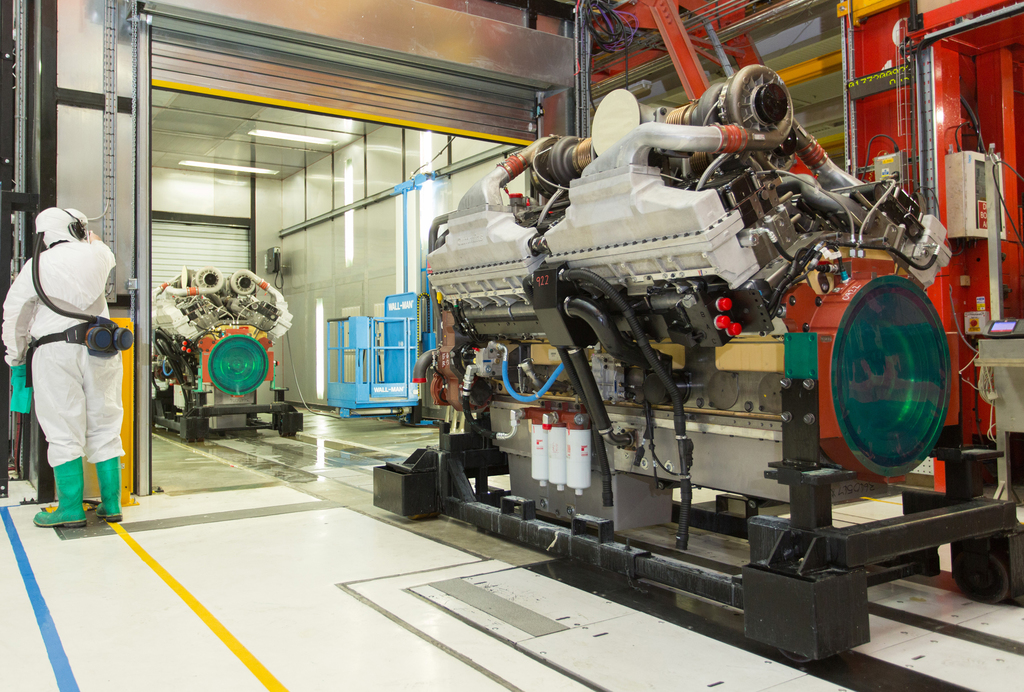

LB Foster Materials Handling has begun work on an automated engine transfer contract for the engine manufacturing plant of Cummins in Daventry.

Every engine is spray painted in the specific colour requested by the customer. The prestigious contract awarded to LB Foster is for two automated systems to transport the engines through two new paint processing lines. Both lines have been designed to process a maximum of 10 engines at a time, each weighing up to 12 tonnes. One line has already been finished with the second due for completion later this year.

Each line is split into two in-floor towline conveyors divided by a paint spraying booth. At the start of the process an engine is picked up by an overhead crane, secured onto a cart before starting its slow journey down the line, where it first enters the engine wash facility. This is followed by a trim process where sections of the engine which do not require painting are masked off.

Another crane is then used to position the engine into the paint spraying booth and from there it is put back onto another cart to be towed by the second conveyor to the end of the line. This process transports the engine into the drying oven, through post paint trim, inspection and then finally it is transferred by crane onto a shipping skid.

"Safety of our employees is paramount, using the new automated line we have taken away many of the manual processes. At the end of each takt time alarms sound and a system of sensors ensure that operators have cleared the area for the engines to automatically move up to the next process," says Ian Bennion, manufacturing engineering leader for Cummins

"In addition, we've increased our engine throughput and improved efficiency by processing engines more quickly and moving them smoothly down the line in a disciplined way."