|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Robots | >Robots make the cut |

Editor's Pick

Robots make the cut

16 December 2014

According to Mitsubishi, robots are particularly well suited to the food processing industry. “They are very flexible and can hold several programmes in their memory so they are able to easily switch from one production task to another," says the company's John Rowley.

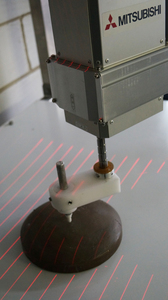

One example of a successful robot application is slicing iced cake, where conventional automation would lead to the cake smearing onto the white icing. Instead a solution for achieving a clean cut with no smearing has been developed using an ultrasonic knife mounted on a multi-axis robot arm that can generate a complex motion profile to simultaneously cut through the cake and synchronise with its movement along on a conveyor.

This solution proved lower cost than other options that were considered, reduced wastage, increased throughput and proved hygienic and easy to clean.

Elsewhere a Mitsubishi Electric robot has been used to achieve something that just a few years ago would have been thought impossible, the emulation of intuitive human cake icing movements.

Quasar Automation wanted to create a system that could neatly apply icing or other embellishments to celebration cakes regardless of irregularities and imperfections in the cakes’ surface. To achieve this they have integrated a ceiling-mounted food safe robot from Mitsubishi Electric with a vision system and data processing software from Scorpion Vision.

The top of any cake is far from smooth; in fact each one is uniquely uneven. When applying writing, such as ‘Happy Birthday’, or an image, the decorator intuitively adjusts to allow for the irregularities. Early attempts at automated icing effectively used 2D images, which distorted on the rough surface and rarely looked perfect.

Quasar specialises in automation for the food industry and in recent years has developed a growing interest in the potential of robots for food applications, so is particularly interested in Mitsubishi’s new F-series robots which include FDA, NFS and Food Sanitation Law compliant robots. These are based on a revolutionary new mechanical design and can be floor, wall or ceiling mounted. A powerful new controller and other high performance components, means they can attain precise positioning accuracy and high speed movements.

All cabling is fully enclosed for total hygiene. This includes pneumatic tubing and an Ethernet connection for specialist functions.

For the cake icing application, Quasar decided to use the F-series robot, ceiling-mounted in a dedicated cell. Utilising the Ethernet cable, a machine vision camera is mounted on the robot and the first step of the operation is to track the camera back and forth above the cake’s surface so that a 3D mapping of all the irregularities is produced.

The vision system was developed with Scorpion Vision, whose Windows-based software can be combined with Gigabit Ethernet digital industrial cameras and bespoke lighting. The Windows format is familiar to almost everyone, so the system is far easier to use than those based on proprietary software.

With the 3D mapping compiled, the 2D image or decoration is compared to it and adjusted for any surface irregularities. Although this represents a substantial amount of data processing, it typically takes only about one second. From this data, the tracking path for the robot to apply the icing is calculated.

- Strategic partnership to meet industrial drive demands

- Futureproofing operations with cobots

- Mitsubishi Electric technology helps train future engineers

- Control package

- Raising the bar in partner excellence

- Why industrial automation needs TSN

- Flexible food safe robots feature a greater working area

- Mitsubishi Electric launches two next generation controller ranges

- Driving innovation on the warehouse floor

- Food chain traceability

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- NUMBER OF ROBOTS IN UK ON THE RISE

- The future is bright - The future is automation!

- High Demand For Grant

- More Capacity, Less Space

- FREEBIRD - THE THIRD DIMENSION

- PRECISION ROBOT CELL FOR THE PHARMACEUTICAL INDUSTRY

- ROBOT SALES REACH ALL TIME HIGH