|

Charlotte Stonestreet

Managing Editor |

| Home> | CONTROLS | >Flow Control | >Hazardous area pneumatics |

ARTICLE

Hazardous area pneumatics

08 June 2015

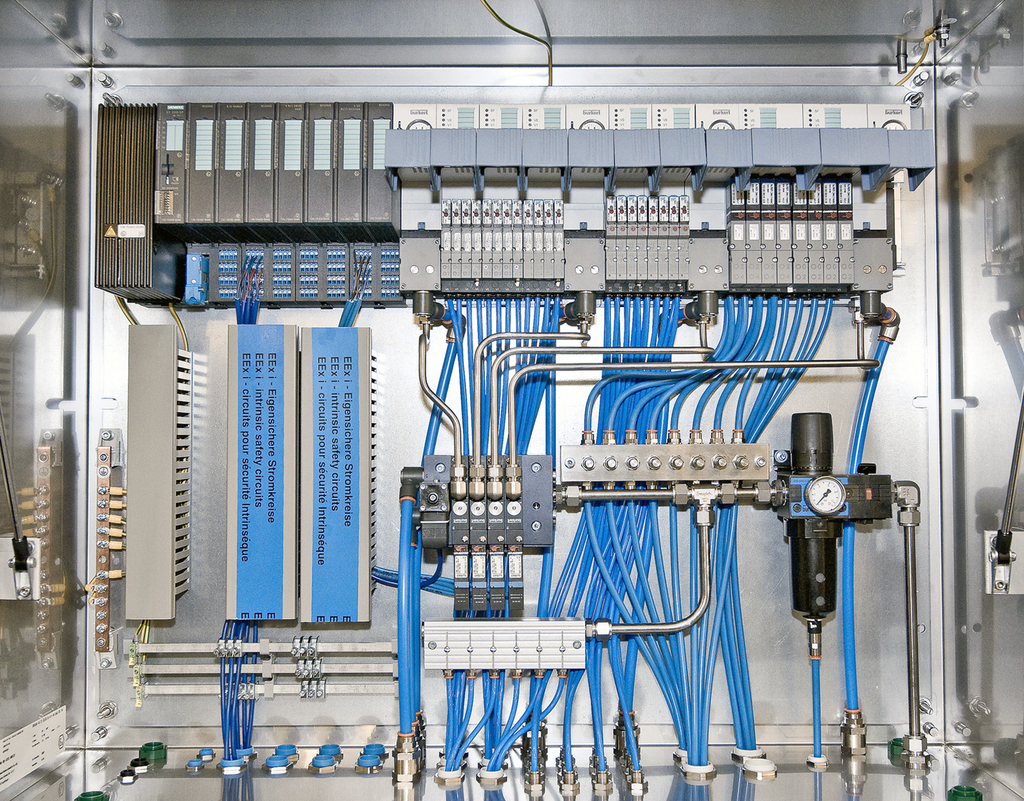

The combination of Bürkert's AirLINE Ex 8650 valve islands and Siemens intrinsically safe SIMATIC ET 200iSP distributed I/O system is providing a safe, compact and modular pneumatic control solution for a global drinks company in Scotland.

The AirLINE EX 8650 system offers the key benefits of substantial reductions in cabinet space, wiring, documentation and validation, reducing the complexity of the task and reducing costs for the client.

The 8650 delivers these benefits by combining EEx ia classed solenoid valves with modules from the ET 200iSP system and Fieldbus communications, providing users with a complete ATEX certified unit for use in zone 1/21.

MORE FROM THIS COMPANY

- Kempston Controls becomes Midlands distributor for Bürkert valves

- Process control valves – making the right choice

- Health care case study

- Modulating control valves help brewery secure productivity

- Do SMEs need to push for more process automation in food & bev?

- Don’t let ATEX restrict your plans

- Simplifying industrial process automation with IO-Link

- Energy saving with process valves

- Keeping control valves clean

- Hydroformed diaphragm valve bodies

RELATED ARTICLES

- REGULATE FLOW

- FLOW CONTROL PRODUCT SEALS

- Verify Flow Controllers

- FUEL SAVINGS OF UP TO 30%

- ACCURATE POSITIONAL PERFORMANCE

- LARGE VALVE POSITIONER

- Fuel-cell race car relies on Bürkert valve technology

- Affordable Valve Management

- Multi-Finction Filtration Controller

- Air Flow & Pressure Switching Point Adjustment

OTHER ARTICLES IN THIS SECTION