|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Inspection | >Sensitive in-line inspection |

Sensitive in-line inspection

18 October 2015

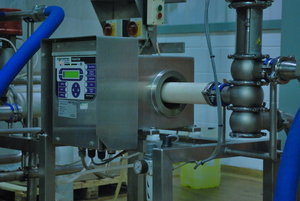

Fortress Technology has just installed its fifth Phantom pipeline metal detector at Shoda Sauces in Abertillery, Wales.

The in-line inspection system is the most sensitive method available for screening piped sauces of varying viscosities, and since purchasing its first Fortress equipment in 2004; the Asian sauce producer hasn’t received a single customer report of metallic contamination from products leaving its factory.

"If we look back over the last eleven years, since we started working with Fortress, we can honestly say we have had zero incidents with metal. Fortress metal detectors are like the ‘Fort Knox’ of the inspection world - nothing gets past them; they are completely failsafe,” said Gareth Law, engineering manager, at Shoda Sauces.

- Multi-machine data connection package

- Multi-aperture metal detector

- Automated label inspection solution

- Safeguarding food with real-time reporting

- Combining food safety strengths

- Helping SME food factories be cyber-smart

- Self check software

- Metal detector testing times

- Travelling food safety expo

- tGARD IN ACTION

- STAINLESS STEEL SENSITIVITY

- EXTEND MOBILE INTO MAINTENANCE

- Thermal Imager At Reduced Price

- Protect Plastics Production

- THAT TAKES THE BISCUITS

- BROAD CAPABILITY

- Free Pressure Module or Gauge

- Combine SCADA and asset maintenance on a mobile device…with EXTEND7000 for IBM Maximo

- Troubleshooting Simplified

- Vibration Meter