|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Machinery Safety | >Safety & productivity |

| Home> | MACHINE BUILDING & ENGINEERING | >Sensors | >Safety & productivity |

Editor's Pick

Safety & productivity

01 March 2016

At MACH 2016 safety and manufacturing specialists from SICK will demonstrate its new DFS60S Pro safety encoder, microScan3 safety laser scanner and deTec4 Prime safety light curtain, all designed to increase uptime and efficiency in automated production and warehousing environments through more dynamic safety.

“Dynamic safety is an enabler of improved productivity in the Industry 4.0 Smart Factory,” explains Dr Martin Kidman, safety specialist from SICK UK. “We’ll be introducing technologies developed to meet the needs of a more connected and fast-moving production environment.

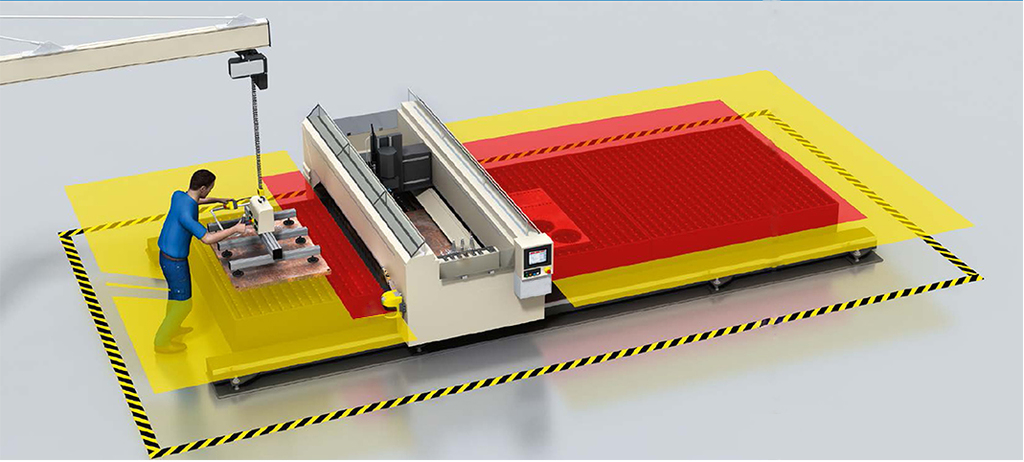

“Instead of cumbersome fenced-off areas that exclude personnel and introduce long downtimes when access is required, SICK is developing its industrial safety products to enable better human-machine collaboration through safe motion control and uninterrupted production with flowing protective fields.”

SICK will be showing its DFS60S Pro incremental safety encoder, enabling motion to be safely monitored in Automated Guided Vehicles (AGV’s) or in machinery requiring frequent operator interaction. The DFS60S Pro enables safe operator interaction at reduced speeds without the need to stop the machine.

Especially when teamed with the Flexi Soft FX3-MOC Drive Monitor, the DFS60S Pro permits safe working without loss of productivity during routine operations such as piece part loading, magazine replacement, adjustment on machining centres or splicing of material on reel-fed machinery. Using a single DFS60S Pro, the rotating shaft speed can be monitored as part of a safety function with a required performance level of PLd / SIL2. If using two encoders, PLe / SIL3 can be achieved.

With the microScan3, SICK is launching a new generation of safety laser scanners at MACH 2016. SICK has revised and optimised every detail of its laser scanner technology to set a new benchmark for individual safety and workflow efficiency.

With its patented safeHDDMTM scanning technology, the microScan3 has a compact and rugged design with a large 5.5m protective field and a scanning angle of 275°. The microScan3 is designed for long life, after which rapid device changeover is ensured through its Smart connectivity, configuration memory and easy commissioning with SICK’s new Safety Designer software.

The versatile deTec4 Prime Safety Light Curtain, also launched at MACH 2016, adds extra functionality and flexibility to complement the highly successful deTec4 Core. The deTec4 Prime offers a scanning range up to 21m and is available in both finger (14mm) and hand protection (30mm), making it suitable even for exceptionally wide machines. Configured simply, it is suitable for a wide variety of applications. Commissioning is quick and safe and up to three deTEc4 Prime safety light curtains can be cascaded minimising wiring complexity.

Concludes Martin Kidman: “With the deTec4 Prime, SICK has produced yet another functional safety device optimised for maximum uptime through ease of connectivity and quick commissioning whilst meeting the most stringent international safety standards.

“SICK has led the way in industrial safety for more than half a century and these latest product launches represent the next generation of devices, ready for use in the Industry 4.0 Smart Factory.”

SICK will also be demonstrating its full range of Smart Sensors at MACH 2016, including the new Trispector 3D Vision Sensor, and its full industrial instrumentation product range.

- Easy, standalone RFID

- Achieve more with mobile robots using SICK modular sensor solutions

- Ten second sensor change

- Simple path to safe productivity

- Vision system delivers production gains

- Smart sensor technologies

- Programmable 3D camera

- APP Maximises Barcode Potential

- Digital twins: How sensor data keeps it 'real'

- Harnessing power of AI

- MAKING SENSE OF SAFETY

- Thermal Imagers for Diagnostic Routines

- Custom String Pot Sensor

- Handwheel Valve Position Indicators

- High Temperature Rating

- THERMAL IMAGERS FOR DIAGNOSTIC ROUTINES

- Fibre-Optic Sensors

- Inductive Sensor Normally Closed

- Submersible gauging level transmitters

- Modular Heavy Duty Interlocks