|

Charlotte Stonestreet

Managing Editor |

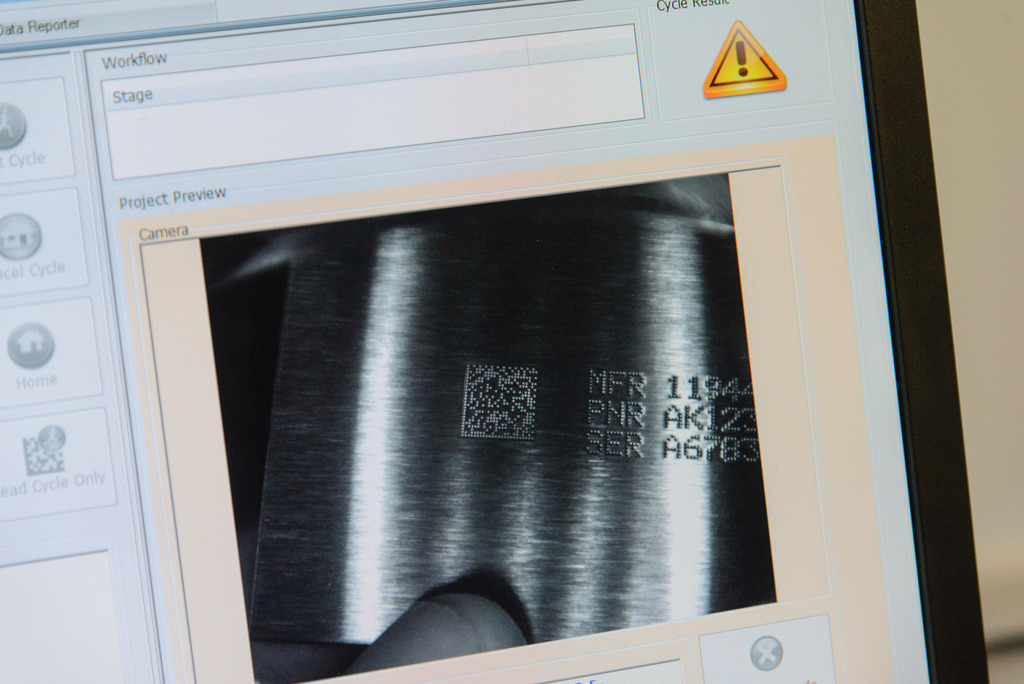

Control & traceability software

18 October 2016

Pryor Marking offers Smart Factory solutions by providing networked systems and software that can store and analyse manufacturing data.

Pryor's quality control software offers a variety of advanced functions which can dramatically reduce quality escapes in any manufacturing environment. Used across all processes, data capture provides a powerful solution to improving the quality of manufacturing.

Pryor traceability software enables manufacturers to log every item that has been scanned and link them to assemblies or groups. Rather than recalling an entire fleet of products, the software can instantly identify the specific product containing a possible defective component which ensures quick solutions to critical issues.

Some of its functionalities include:

- Creating a virtual assembly to log and trace unique components within an assembly

- Logging manufacturing data and variables against unique component IDs for a full manufacturing history

- Process control – with the use of gated manufacturing steps

- Using machine vision tools to check marking quality and ensure durability through the life cycle

- Produce extensive and detailed reports of manufacturing data

- Anniversary Edition Module

- FREE ‘DROP-IN’ WORKSHOPS

- Generate Motion Programs Directly from Your CAD Drawing

- B&R NEW WEBSITE

- Efficient integration - B&R

- Delta DOP-B HMI

- Mitsubishi Electric technology helps train future engineers

- Modeling Software

- Firmware option reduces programming

- Nuclear arm control