|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Inspection | >Chocolate mould monitoring |

| Home> | AUTOMATION | >Monitoring | >Chocolate mould monitoring |

| Home> | AUTOMATION | >Vision Systems | >Chocolate mould monitoring |

Chocolate mould monitoring

18 October 2016

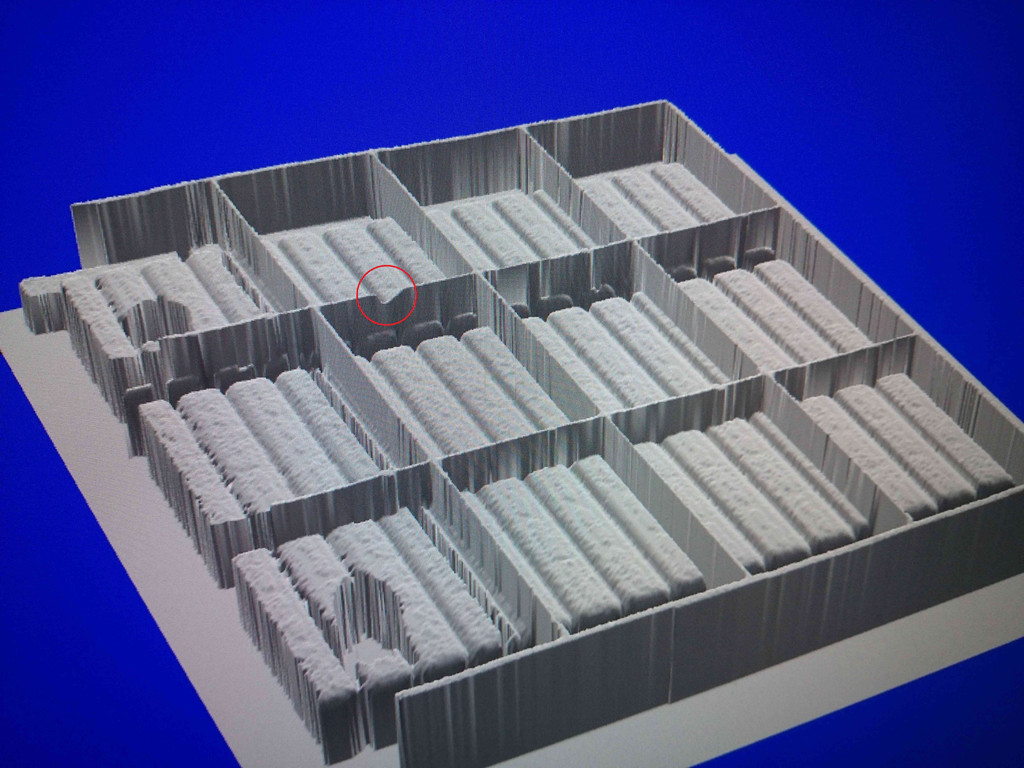

At VISION 2016 in Stuttgart, Berlin-based Bi-Ber will present a newly developed 3D scanning system using a laser-profile sensor for mould breakage detection in chocolate moulds.

Using the triangulation method, the scanner reliably detects faulty break-offs on chocolate moulds immediately during manufacture. The system features a resolution of up to 1.6 mm perpendicular to and 0.5 mm level with the observation plane. Even the smallest irregularities, such as chocolate mix splashes, can be reliably distinguished from broken-off plastic pieces.

In addition, the use of multiple DS1300 cameras from Cognex enables wear monitoring of moulds even at very broad scan widths. The system can be easily adapted to various applications, can be custom-dimensioned and is geometrically adjustable to any given installation environment.

- No related articles listed