|

Charlotte Stonestreet

Managing Editor |

| Home> | DRIVES & MOTORS | >Soft Starters | >Energy efficient option |

Energy efficient option

29 June 2017

Energy conscious plant operators are reported to be installing soft starts at an unprecedented rate, so that they save energy by stopping intermittent duty motors when they are actually not in use.

Until recently it has been conventional practice to leave motors idling between duty cycles, but increasingly this is now seen as wasteful of energy – especially with recent rapid rises in electricity prices. Idling motors also exhibit very poor power factor, contributing to kVAr charges.

“In the past there were sound engineering reasons for doing this,” explains Scott Harvey of Softstart UK, one of the beneficiaries of the change of practice. “The wear and tear on the electrical and mechanical elements of a drive system at start-up is quiet considerable, so you were offsetting this against the energy consumption.”

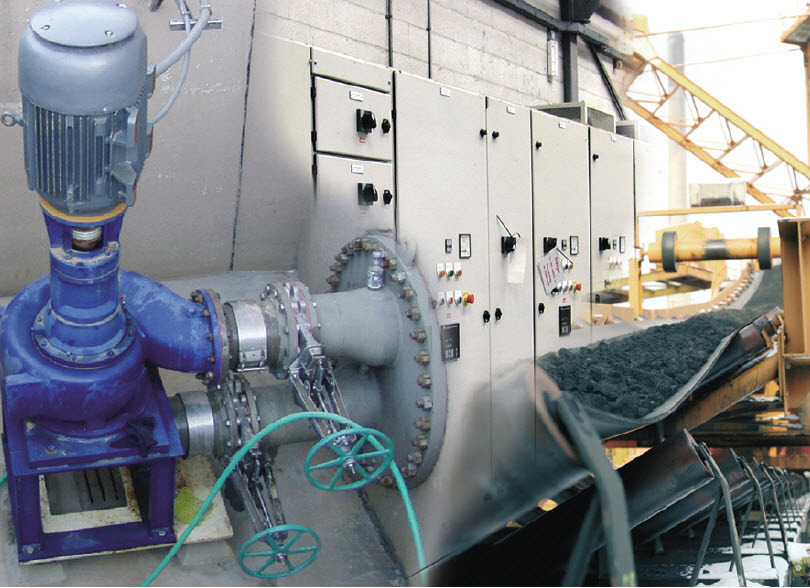

However, the growing emphasis on reducing carbon emissions has made plant engineers reexamine many of their business practices. Soft starts reduce the electrical and mechanical shock loads and consequential damage by bringing a motor up to speed far more smoothly than direct-on-line starting. This means the motor can be stopped when not in production and started smoothly and efficiently when required, without concerns over electrical and mechanical system stresses.

Harvey says that it is very easy to make a financial case for installing a soft start on a large drive system and so his company has seen a massive upswing in orders for medium voltage soft starts. “For instance we are just completing an order for an order for 7 x 11kV 1MW soft starters for compressors for a Scottish glass manufacturer.

As well as three 6.6kW 1.1MW systems for offshore Aberdeen for an Oil & Gas platform. Two further units are currently in production for offshore for Petronas Samarang field. The trend is almost as pronounced in the smaller off-the-shelf soft starts.

Harvey reports that sales of 4KW-600kW units have quadrupled in less than 15 months. “This includes a couple of big call-off orders for OEMs, one-off sales and ongoing projects where we are working our way through a customer’s plant to improve the energy efficiency of one machine after another.”

- Hazardous area system design video

- Softstart achieves best Delta sales growth

- No run of the mill starter

- VSD control cabinets for hire

- Getting ready for better times

- Multi-Voltage capability for pump test station

- Bringing Life To The Desert

- Softstart UK & Delta Electronics in strategic partnership

- Field Oriented Control