|

Charlotte Stonestreet

Managing Editor |

| Home> | CONTROLS | >Flow Control | >Gas programming functionality |

Gas programming functionality

03 January 2018

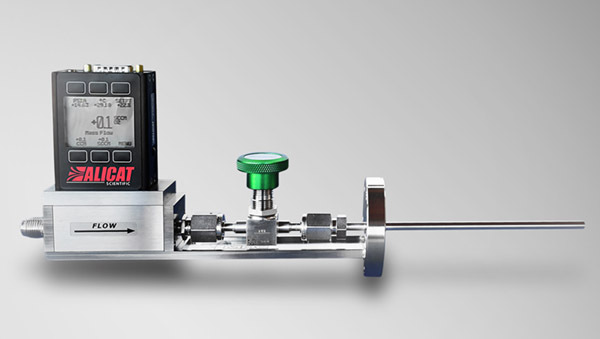

Alicat Scientific’s MCE mass flow controllers have been integrated into MDC Vacuum Products’ XpressStick MFC Gas Stick. With precision control of gas flows of up to 20SLPM and onboard display, Alicat’s MCE provides gas programming functionality to the gas connection module, which links pressurised gas inputs to vacuum chambers.

The Alicat MCE accurately controls gas flow rates as low as 0-0.5sccm full scale or as high as 0-20slpm full scale. With 20 to 50 millisecond control response times to setpoint changes, the MCE improves vacuum coating end products and helps eliminate target poisoning.

The all-in-one design of the XpressStick MFC gas stick eliminates complex hardware specification in processes which include a combination of specialty gases, pressure, precise regulation, and vacuum. Its easy programming and precise gas control system allows users to go from bottle to process in one simple step. Designed to meet ultra-high purity process requirements, the XpressStick is also offered in a stainless steel model for corrosive environments.

With the MCE’s zero warm up time, the XpressStick is ready to control process flows in just one second, with real time mass flow, volumetric flow, absolute pressure and temperature data, fully compensated for temperature and pressure. The gas module is programmed directly through the MCE’s integrated display, with easy changes to gas type using the on-board gas calibrations.

“Fast response time, accuracy, and reliability were all key criteria in choosing an MFC instrument for our XpressStick,” explained MDC vice president of Engineering & Technology, James Moore. “Based on past experience with Alicat, we knew that they could deliver all three, with an integrated display that enables our all-in-one design.”

- REGULATE FLOW

- FLOW CONTROL PRODUCT SEALS

- Verify Flow Controllers

- FUEL SAVINGS OF UP TO 30%

- ACCURATE POSITIONAL PERFORMANCE

- LARGE VALVE POSITIONER

- Fuel-cell race car relies on Bürkert valve technology

- Affordable Valve Management

- Multi-Finction Filtration Controller

- Air Flow & Pressure Switching Point Adjustment