|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Brakes | >Brake resistor technologies: Lessons from the field |

| Home> | DRIVES & MOTORS | >Brakes | >Brake resistor technologies: Lessons from the field |

| Home> | MACHINE BUILDING & ENGINEERING | >Materials & Components | >Brake resistor technologies: Lessons from the field |

Editor's Pick

Brake resistor technologies: Lessons from the field

02 December 2025

Steve Hughes explores how braking resistor construction affects long-term reliability, safety, and performance

BRAKING RESISTORS are critical safety components within electric drive systems, converting excess regenerative energy into heat to prevent overvoltage and protect sensitive components. As energy efficiency and control precision have improved, so has the demand for braking solutions capable of withstanding harsh environments, vibration, and rapid duty cycles.

This article examines three key construction methods – tubular, frame (register or grid), and aluminium clad – exploring their strengths, limitations, and lessons learned from real-world applications in industrial and transport sectors.

Tubular resistors

Tubular resistors remain one of the simplest and most established braking resistor types. Built around a ceramic or fibreglass core with resistance wire wound along its length, the assembly is often cement-coated for insulation and rigidity. This design offers simplicity and low cost but also introduces limitations. Voltage withstand capability is restricted because windings are closely spaced, increasing the risk of arcing under transient or surge conditions. With limited ingress protection, typically IP00 to IP20, tubular resistors are susceptible to contamination and moisture, and can produce audible noise in certain circumstances.

In legacy lift and conveyor systems, tubular resistors are still common; however, exposure to vibration and humidity can cause insulation breakdown, winding displacement, or coating failure. In one recent retrofit project, open-tube resistors near moisture sources suffered corrosion and thermal fatigue within six months. The early failures highlighted sensitivity to moisture and temperature cycling. While adequate in clean, temperature-controlled settings, they are increasingly unsuitable for demanding or outdoor environments.

Frame (register/grid type) resistors

Frame resistors represent the next step in design evolution. They consist of flat resistance elements (often stainless steel or nickel-chromium ribbons) mounted on insulating supports to form a grid. The spacing between windings improves voltage withstand and cooling airflow. Assemblies can be stacked to meet specific power and resistance values, offering a modular, serviceable solution. They are often used for generator testing and neutral-earth applications.

Despite advantages, frame resistors are still limited by their open construction. Their maximum protection level rarely exceeds IP20, leaving them exposed to dust and moisture. In vibration-intensive environments, such as cranes or rail vehicles, mechanical stresses can lead to failures and when force-cooled, maintaining the cooling system can become an issue. Nevertheless, they remain a practical middle ground for indoor industrial drives, balancing cost and flexibility.

Aluminium clad (encapsulated) resistors

Aluminium-clad resistors have become the benchmark for reliability and safety in demanding drive applications. The resistance element is embedded within an insulated, aluminium extrusion and filled with a thermally conductive compound such as quartz or ceramic filler, the result is a sealed, robust assembly with ingress protection from IP20 up to IP66 and unlike Tubular or frame-type resistors, the winding is totally isolated; therefore, drive system damage is avoided in the event of a failure.

Industrial projects have demonstrated the resilience of encapsulated resistors under harsh conditions. Units subjected to prolonged salt-mist and vibration testing maintain consistent resistance and insulation strength. They also integrate safety features such as embedded thermal switches for overload detection. The encapsulation dampens acoustic noise and isolates the windings from contamination, making them ideal for outdoor drives, rail, and renewable applications. Their high dielectric strength enables reliable operation up to 1000V and impulse loads well above ten times nominal rating.

Industry developments

The shift from open to sealed construction reflects broader industry trends. The adoption of higher switching frequencies, compact enclosures, and mobile installations has increased thermal and mechanical demands. Failures in older resistor types – cracked formers, corroded terminations, non-tripping thermal switches – underscore the need for more reliable solutions. Modern designs now undergo salt-mist, shock, and vibration testing to international standards. The use of IP54-rated anodised housings and fully sealed extrusions marks a significant leap in safety and reliability.

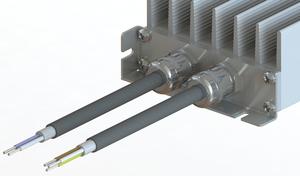

Under EN 61800-3, braking resistors form part of the overall Power Drive System (PDS). Open designs and cabling can act as antennas, coupling high-frequency noise into surrounding equipment. Aluminium-clad resistors provide a grounded, conductive barrier that functions as a Faraday cage, reducing radiated emissions. When installed with screened or armoured cable and a 360° braid bond (Figure 4), RFI currents remain confined within the screened path, improving compliance and immunity, critical in rail, renewable, and automation systems governed by EN 61800-3 and EN 50121.

Comparison and outlook

Viewed collectively, tubular, frame, and aluminium-clad designs show clear progression. Tubular resistors, though economical, offer limited resilience. Frame resistors offer improved performance and modularity, but remain susceptible to environmental stress. Encapsulated resistors, while more expensive, deliver superior protection, performance, and longevity.

Recent projects confirm that the total cost of ownership, not purchase price, should guide selection. Where downtime, access, or exposure are factors, sealed extruded resistors consistently show better lifecycle economics. As energy systems evolve, priorities will favour compact, EMC-compliant, vibration-resistant, and thermally efficient designs. Ongoing advances in encapsulated technology ensure braking systems remain reliable safeguards for modern automation, HVAC, building technology, and transport.

Steve Hughes is director at REO UK

- Ingress protection added to drive peripherals by encapsulation

- The future is (almost) now

- Behind the motion of motor control

- Think tank adds new member

- Chokes and filters in HVAC applications

- When water & electricity do mix

- Water-Cooled Braking Resistor

- Enclosure solution for REO chokes and inductors

- Food on the move

- 3D printer speeds time to market