|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Machinery Safety | >Be on guard for cobot safety |

| Home> | AUTOMATION | >Robots | >Be on guard for cobot safety |

Editor's Pick

Be on guard for cobot safety

01 March 2023

While robots designed for use in collaborative applications offer exciting possibilities for industry, they are not without particular safety considerations. Stewart Robinson looks at the relevant legislation

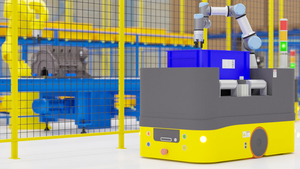

ISO 8373 DEFINES an industrial robot as: “An automatically controlled, reprogrammable, multipurpose manipulator programmable in three or more axes, which may be either fixed in place or mobile for use in industrial automation applications.” Robots are now being specifically designed to work alongside humans in a ‘collaborative workspace’, so they can perform tasks simultaneously with the robot often operating in the human-occupied workspace without safety guarding.

However, not all ‘collaborative robots’ are guard-free, depending on their function and related safety requirements. Besides the robot itself, the collaborative application will include an ‘end effector’, that is the tool adapted on the robot arm with which the robot performs tasks, and the objects moved by it. In tandem with this new way of working, there of course comes new safety concerns.

As well as manufacturing, there are many other sectors where collaborative applications deliver distinct advantages, including:

- Medical (where robots are used during various medical procedures including surgery)

- Healthcare (where robots perform tasks such as assistance with mobility)

- Service (both domestic and professional applications)

- Space (for example on the International Space Station)

- Defence (for example robots assisting in bomb disposal and wearable robots for enhanced mobility).

The increased need for adequate protection of people from the safety risks associated with industrial robot systems led to the development of EN ISO 10218:2011, an international and European standard which covers the safety requirements for industrial robots. The standard replaced the 2006 version, and is in two parts:

- EN ISO 10218-1:2011 Robots and robotic devices — Safety requirements for industrial robots — Part 1: Robots.

- EN ISO 10218-2:2011 Robots and robotic devices — Safety requirements for industrial robots — Part 2: Robot systems and integration.

In order to ensure that humans are not exposed to unacceptable risks when working collaboratively the current standards describe four separate measures that can be used to provide risk reduction. It is required that at least one of these is fulfilled, in addition to having visual indication that the robot is in collaborative operation.

The four measures are:

1. Safety-rated monitored stop

This measure requires that when it is detected that a human has entered the collaborative workspace, the robot shall be stopped. The stop condition shall then be maintained until the human leaves the workspace.

2. Hand guiding

In this mode the human can guide the robot at the end effector by hand. Additional requirements for safety include safe-limited speed monitoring, a local emergency stop, and the use of an enabling device, which is a three-position device that has to be held in the centre position.

3. Speed and separation monitoring

In this mode, the robot must maintain a specified separation distance from the human and operate at a predetermined speed. This measure requires careful risk assessment and needs to take account of safety distances, which should include the consideration of approach speeds of parts of the human body as described in EN ISO 13855.

4. Power and force limiting by inherent design or control

In this mode the power and force of the robot actuators need to be monitored by safety related control systems to ensure that they are within limits established by a risk assessment.

It is required that at least one of these requirements needs to be fulfilled, in addition to having visual indication that the robot is in collaborative operation. In all four of the measures described above, the safety-related control system that provides this functionality needs to meet either:

- Safety Performance Level d (PLd), with Category 3 architecture (the identified level to which the safety related parts of a control system resist faults and their subsequent behaviour if a fault occurs) as outlined within the standard EN ISO 13849

or

- Safety Integrity Level 2 (SIL 2) with hardware fault tolerance (HFT) 1, as set out in EN IEC 62061.

Safety first

While EN ISO 10218 contains some guidance on collaborative applications, with the rapid pace of technological development, it was widely acknowledged that this guidance needed to be enhanced. Consequently, a Technical Specification (ISO/TS 15066 Robots and robotic devices — Safety requirements for industrial robots - Collaborative operation) was published in 2016.

ISO/TS 15066 covers:

- The design of the collaborative workspace

- The design of the collaborative operation

- Methods of collaborative working

- Changing between: Collaborative/non-collaborative; Different methods of collaboration

- Operator controls for different applications

The methods of collaborative working ‘speed and separation monitoring’ and ‘power and force limiting’ are particularly elaborated on in ISO/TS 15066. This includes recommendations for ‘biomechanical limits’ of pain thresholds for specific parts of the human body.

There are also working groups of the standards organisations reviewing various aspects of human-machine interactions, which will also inform the development of future standards. For example the next version of ISO 10218-2 will almost certainly contain not only significant parts of ISO/TS 15066 but also guidance on the testing required to verify Power and Force Limiting (PFL). But for now, EN ISO 10218 Parts 1 and 2, and the ISO/TS 15066 specification defines the safety requirements for the sphere of collaborative robots, with the most relevant published guidance being contained in EN ISO 10218.

Guidelines from HSE

Published in 2012, a Health & Safety Executive (HSE) Research Report, (RR906) - Collision and injury criteria when working with collaborative robots, also offers some useful guidance.

The introduction to the HSE report states that “this study explored the safety, reliability and evidence for the force limits defined by the draft TS 15066, and of the methods for testing them. It also addressed whether the proposed approach in the draft TS 15066 is likely to adequately protect people from the risks. Risk assessment of potential collision scenarios, human reliability and behaviour issues, and equipment failure modes and rates are discussed, as is the adequacy of personal protective equipment against collision injuries.”

The report identifies several areas that the HSE considers need more consideration within ISO/TS 15066. For example, it concludes that the psychological, behavioural and organisational aspects affecting the level of human-robot collision risk, along with the effects of human movement velocities, are not strongly represented in ISO/TS 15066. The HSE also points out that the frequency of injury is not included in the criteria for acceptable collision limits.

The future of manufacturing

Robots designed for use in collaborative applications are now expanding the possibilities of automation and, as they are a core element of Industry 4.0, manufacturers are integrating greater numbers of such applications factory wide.

While the advent of collaborative applications offers exciting possibilities for industry, some end-effectors may create hazards, especially as contact between the collaborative robot and the operator can lead to the possibility of collision. It is therefore vital that a complete risk assessment is undertaken before a collaborative application is deployed, as you would with any machinery in the workplace. This must cover the intended use of the robot, as well as any reasonably foreseeable misuse, with the basis for this risk assessment being EN ISO 12100, in order to provide a presumption of conformity with the Machinery Directive in the European Union and the Supply of Machinery (Safety) Regulations 2008 in the UK.

Stewart Robinson is principal engineer and functional safety expert at TÜV SÜD

Key Points

- Not all collaborative robots are guard-free, depending on their function and related safety requirements

- EN ISO 10218:2011 is an international and European standard covering the safety requirements for industrial robots

- HSE Research Report (RR906) Collision and injury criteria when working with collaborative robots, also offers useful guidance

- Electrical safety training

- Cyber security vulnerabilities & how to mitigate against them

- Wireless module warning

- Machinery & UKCA marking

- New UK divisional director

- EMC Centre Of Excellence

- Machinery safety risk assessment

- Securing the IoT

- Safety in smart manufacturing

- Electromagnetic machinery safety service

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- MAKING SENSE OF SAFETY

- NUMBER OF ROBOTS IN UK ON THE RISE

- Handwheel Valve Position Indicators

- The future is bright - The future is automation!

- High Demand For Grant

- More Capacity, Less Space

- Modular Heavy Duty Interlocks