|

Charlotte Stonestreet

Managing Editor |

| Home> | CONTROLS | >Motion Controls | >What to look for in a motion control feedback device |

| Home> | DRIVES & MOTORS | >Servo Motors & Drives | >What to look for in a motion control feedback device |

Editor's Pick

What to look for in a motion control feedback device

07 November 2025

WHEN IT comes to the world of motion control, it’s easy to take your feedback device for granted. After all, it’s a small part of the system and is typically tucked inside the motor housing, out of sight and out of mind. However, the impact this seemingly minor component has on a system’s accuracy, performance, reliability, and ease of integration is hard to overstate.

Today’s servo systems depend on accurate, consistent feedback to maintain position, control speed, and execute complex motion profiles. But not all feedback devices you can specify are created equal. Traditional encoders or resolvers still do the job in many applications, but application requirements increasingly need devices that go beyond the basics. Design engineers also want faster integration and less testing time. Modernising your feedback device can mean reducing wiring, simplifying setup, or eliminating long-standing compromises on resolution, accuracy, and smoothness of motion.

Whether you’re specifying a new servo system or looking to simplify an existing design, it’s worth asking: what do you actually need your feedback device to do, and what’s now possible?

What are you really looking for?

Most engineers don’t start out looking for a feedback device. They’re looking for performance, reliability, and a system that behaves the way it’s supposed to, every time. That means starting with the right questions: Not “which sensing technology is best?” but “what performance does my application need to achieve?”

At the most basic level, your feedback device needs to deliver the resolution and accuracy required to drive the motion loop effectively. Too little, and you’ll see ripples in motion, jitter in position holds, vibration in the machine, or just plain inaccurate positioning. Too much, and you might be paying for more capability than needed. Mechanics connecting to a motor shaft can only so accurately connect to the part of the machine doing the work which is where the motion really matters.

Other considerations quickly come into play, such as how smooth the motion is, how noisy the signal is, and how much bandwidth does it offer compared to your requirements. Fortunately, these are mostly straightforward questions, and most engineers know how to weigh them up.

But modern feedback devices also bring in another category of features that extend beyond the basic specs and simplify the machine as a whole. This is where many of today’s biggest gains are being made.

They include:

- Simple cabling: Servo systems used to rely on dedicated feedback cables, sometimes requiring 13 or more wires just for feedback. That meant bigger cabinets, more connectors, tighter bends through cable trays, and more hands-on work during installation.

Modern single-cable feedback systems simplify all of that. By taking the motor power cable and just adding two wires for feedback data to fit everything into a single cable, they reduce effort and cut install time. Single-cable can make a major difference on compact machines where space is tight and reduce machine build time

- Built-in motor ID: Many modern feedback devices now include onboard memory that stores the motor’s ID, specs, and even tuning parameters. When connected to a compatible drive, the system can automatically recognise what it’s working with.

That means setup becomes faster, more consistent, and less prone to human error. In systems where motors are easy to mix up – say, a high-speed and low-speed variant sharing identical housing – this auto-recognition helps prevent costly mismatches. It also supports smoother global deployment, especially when machines are shipped across regions with different voltage standards.

- Thermal monitoring: Temperature sensors are vital for protecting motors, but traditionally they’ve required their own wiring back to the drive. With smarter feedback systems, temperature data can now be sent over the same digital link used for position data.

This combination streamlines wiring even further and makes it easier to monitor winding temperatures in real time. The result is better protection against overheating, more consistent performance, and fewer points of failure.

- Functional safety support: In applications where people work close to moving machinery, safety is vital. Some modern feedback devices now support functional safety features directly through the encoder.

These certified encoders allow safety systems to reliably monitor motor position and intervene if motion goes outside expected bounds. Integrating safety at the feedback level reduces the need for extra sensors or relays, simplifies system design, and helps meet compliance requirements without overcomplicating the machine.

The new standard

One feature that’s quickly becoming an expectation rather than a simple nice-to-have is multi-turn absolute feedback. This allows a system to know not just the shaft angle within a single revolution, but how many full turns have occurred, even when the system is powered off.

Without multi-turn tracking, the system has no idea where it is on that axis after a power cycle. The common workaround is a homing routine: the machine slowly moves to a reference point and resets itself. While this works, it’s inefficient and vulnerable to mechanical faults.

Multi-turn absolute feedback lets machines skip the homing process entirely. Power up, and they’re ready to go. That means shorter startup times, fewer moving parts (no home switches), and fewer chances for something to go wrong.

There are several ways to achieve this. Some devices use small internal gearboxes to track turns, but this adds cost, complexity, and physical length to the encoder. These gears also limit usable multiturn range, usually to 12 bits. Other feedback devices use battery backups, which are compact and straightforward, but can potentially create maintenance issues down the line and reliability issues with unscheduled battery failures

Energy-harvesting feedback devices offer a modern alternative to both. These generate just enough power from shaft rotation to store turn counts in non-volatile memory. The result is a compact, battery-free, maintenance-free solution that fits into the same footprint as a basic encoder.

Choosing the right feedback device for the job

So, how do you decide what to specify?

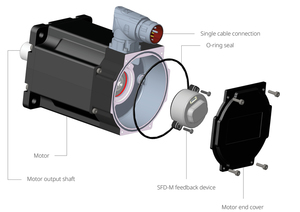

For most applications, a modern digital feedback device with multi-turn absolute capability via energy harvesting, single-cable support, provides motor thermal data, and has motor catalog data is a safe and future-ready choice. Devices like Kollmorgen’s SFD-M are designed to meet the demands of general-purpose motion systems, delivering high performance, low cost, and reduced system complexity.

And if you’re building systems at scale, it’s worth thinking in terms of pre-matched components, such as those supplied by Kollmorgen. Drives, motors, and feedback devices that are designed to work together out of the box reduce integration complexity and speed up development.

Whether you approach feedback at the component level or the system level, the key is to pick devices that reduce the number of compromises your machine has to make.

It’s time to expect more

Feedback devices used to be simple. You picked a motor and got the feedback device it came with. You wired it up and tested whether the included feedback had the resolution and performance you needed. But today’s systems demand more; and deliver more in return. Features like single-cable installation, energy-harvesting multi-turn feedback, plug-and-play configuration, and built-in safety and diagnostics are fast becoming standard in well-designed motion platforms.

You’re not just choosing a sensor, you’re choosing a system that needs to work, reliably and efficiently, every day. That’s why it makes sense to look beyond the component spec sheet and consider how the feedback device supports the system as a whole.

Modern servo solutions like those built around Kollmorgen’s SFD-M show how far this technology has come. These are complete systems designed to simplify integration, support long-term reliability, and give machine builders fewer things to worry about.

- Compact package enables more versatile machines

- Easier and more affordable high-performance motion control

- Self-driving systems

- Washdown servomotor

- Robot-ready frameless servo motors

- Single-cable connection

- Stepper drive with closed-loop position control

- Easy set up servo drive and motor system

- Next generation motion technology

- Servo technology - centralised or decentralised?