|

Charlotte Stonestreet

Managing Editor |

| Home> | CONTROLS | >Motion Controls | >The mechatronic approach |

The mechatronic approach

27 October 2025

Arne Linder explores the benefits and key aspects of applying a mechatronic approach to designing motion systems

WHEN PEOPLE talk about mechatronics, it’s often framed as something futuristic – the next big leap in automation. In truth, it describes something engineers have been working toward for decades: designing machines where the mechanical, electrical, and control systems work together as one.

What’s changed is the level of sophistication we can now achieve, and the expectation that we should. The idea of building a machine from isolated parts, each with its own setup and software, no longer fits how modern automation works. A mechatronic approach instead looks at the entire system as a single organism where the motor, drive, controller, and software are not just compatible, but interconnected. Correctly applied to today’s motion systems, this concept can deliver greater precision, faster commissioning, and easier long-term support.

You can see this in how advanced machines are now designed and developed. Rather than treating electrical, mechanical, and control engineering as separate stages, they’re part of one continuous process: from virtual design and simulation to physical commissioning and maintenance. Each discipline informs the others and the end result is a machine that moves, and evolves, as a unified system.

From components to cooperation

For a long time, setting up a servo system meant – rather ironically, for automation projects – doing everything by hand. Engineers had to enter the motor parameters into the drive manually, refer to look-up tables, and hope nothing was mistyped. Small errors in those numbers could lead to poor performance, instability, or unexpected behaviour. Even something as minor as a misplaced decimal point could have catastrophic consequences and potentially even cause a motor to damage itself or rapidly overheat.

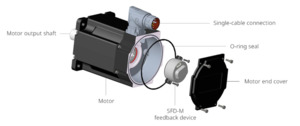

Modern systems, such as Kollmorgen’s own SFD-M feedback device, can take much of that risk away. Today, a properly designed setup can allow the motor and drive to automatically identify and configure each other, loading the correct parameters for torque, current, and speed control without the needs for slow (and potentially incorrect) manual entry. That not only saves time, but ensures that the system performs as designed from the first test move.

This is what we think of as the first stage of mechatronic integration: getting the key elements to cooperate automatically. It may sound simple, but it represents a big step forward for commissioning and consistency. The engineer can focus less on configuration and more on the dynamics of the machine itself.

The next step is bringing that same simplicity to the control layer. Many OEMs have long-standing automation environments and communication protocols they prefer to use. That’s why many of our modern drives are built to operate agnostically, communicating across multiple industrial networks by default. For those developing entirely new systems, fully integrated environments such as the Kollmorgen Automation Suite make it possible to handle motion, PLC logic, safety, and visualisation within a single workspace. It’s a practical example of mechatronics in action – combining mechanical intent and digital control in one place.

Designing for the full machine lifecycle

One of the key aspects of mechatronics is being able to understand how components will fit together and perform as a whole. This is somewhere that modelling and simulation tools can deliver huge benefits, as they allow engineers to explore motor and drive combinations virtually, predicting performance before any hardware is deployed. Later, when motion control and PLC logic are developed in an integrated software environment, coordinated motion even can be tested and refined virtually, often before a control cabinet has even been wired.

And once the machine is operational, a well-integrated system can help to dramatically simplify maintenance and support. For example, when components from multiple vendors are stitched together, identifying the source of a fault can be time-consuming and uncertain – the motor manufacturer says the issue must be caused by the controller, the controller supplier blames the drive, and so on.

A unified system removes that ambiguity, allowing issues to be traced and resolved quickly. It also makes upgrades and replacements more straightforward, as new components can be validated and fitted without redesigning the surrounding system.

This can also be incredibly useful in a world where engineering and production are increasingly globalised and a machine might be designed in Europe, assembled in Asia, and serviced in North America. Rather than having to ship components across the planet and perform countless validation tests every time you make a change to a design, integrated motion platforms and shared digital environments help maintain performance and consistency across those boundaries, ensuring that a design behaves the same no matter where it’s built or operated.

Bridging the mechanical and digital worlds

The ability to connect the physical and digital worlds will only become more important. The growing use of simulation and digital twins aims to bring mechanical, electrical, and control design into a single virtual environment where a complete machine can be tested and validated before a prototype is built. While experience tells us that removing physical testing entirely is unlikely to be the case, each step toward deeper integration brings us closer to incredibly optimised designs out of the box.

Ultimately, the value of mechatronics lies not in any one technology, but in what happens when the pieces come together. Machines built as unified systems are easier to develop, tune, and trust. They run more smoothly, can be maintained more easily, and adapt more readily to future needs.

That is what designing motion as a system means: treating mechanics, electronics, and control not as separate parts of a process, but as a single, cooperative whole that moves exactly as intended.

Arne Linder is product manager at Kollmorgen

- Stepper drive with closed-loop position control

- Next generation motion technology

- Single-cable connection

- Easier and more affordable high-performance motion control

- Electric hybrid

- Self-driving systems

- Servo technology - centralised or decentralised?

- Easy set up servo drive and motor system

- Explosion-proof approvals

- Washdown servomotor

- HARMONIC CANCELLATION

- Integrated Motion Control

- New 4th Generation PH Series Servo Planetary Gears are Largest in Class and offer Engineers even more benefits

- Driving Trends & Developments

- EtherCAT I/O is Tightly Integrated into Aerotech's A3200 Automation Machine Controller

- Galvo and Controller Combination Offers Infinite Field of View and 24-Bit Resolution

- Control systems

- Rail Coupling Minimises Downtime

- Custom Motion System For CT Scanner

- Full Servo Motion Advantages At A Fraction Of The Cost