|

Charlotte Stonestreet

Managing Editor |

Editor's Pick

Reliable analogue value processing

10 January 2020

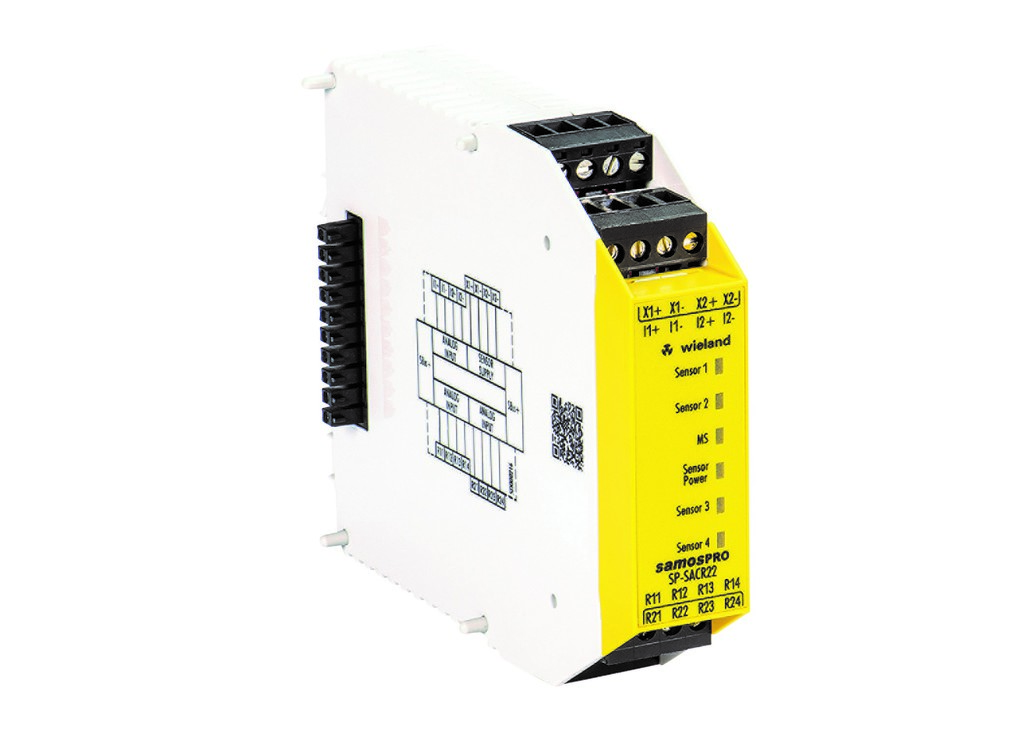

Wieland Electric has added three new input modules to its samos PRO COMPACT safety controller for reliable analogue value processing.

In many applications it is essential that analogue variables such as pressure, flow, and temperature are monitored in order to ensure safe automation so Wieland Electric has added three new input modules for analogue signals to it’s samos PRO COMPACT safety controller. With three new input modules, SP-SAC, SP-SAR4, and SP-SACR22, Wieland has made it possible to reliably detect and further process analogue signals aswell.

The new modules support sensors with a 0/4-20mA interface as well as temperature-dependent resistors like Pt/Ni sensors and deliver their analog data to the samos PRO COMPACT safety controller. The analogue values can be monitored with the new and reliable “Limit”, “Range”, “Relation”, and “Difference” function blocks in user programs created with the license-free programming software samos PLAN 6. These efficient function blocks enable comparative or arithmetic operations involving analogue data as well as scaling of the measured current values, and the presentation and visualization of the analogue values in samos PLAN 6.

Integrated USB and ETH interfaces enable access to the system at any time, whilst Industrial Ethernet protocols have been included from the outset. Further additional gateways for fieldbuses will make any necessary integration into a wide variety of industrial networks incredibly simple. This ensures greater transparency for the user as the analogue values can easily be transferred to other control systems. Up to three different fieldbus systems can be operated from one samos PRO COMPACT in parallel.

These modules are ideal for use in process engineering applications in the glass, metal, or chemical industry or also in specific areas of mechanical engineering such as conveyor systems, presses, and CNC machines. To ensure safe operation of the system, all inputs and outputs have unique visual displays that clearly show the operating status at any time. The samos PLAN 6 software provides a customised report, ensuring that the plant’s documentation complies with all applicable regulations. The modules meet all safety standards, including SIL CL 3 according to EN 62061 and PL e / category 4 according to EN ISO 13849-1.

- New generation of terminal blocks

- Compact safety controller with integrated motion functionality

- Managed switches provide full network control

- Flexible contact inserts

- MAKING THE MOST OF SAFETY BENEFITS

- Wieland introduces podis power bus system

- Full network control

- Project planning tool

- Automation technology for machines & plants

- Fast, safe installation