|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Machinery Safety | >Smart sensors & machinery safety |

| Home> | AUTOMATION | >Sensors | >Smart sensors & machinery safety |

Smart sensors & machinery safety

06 August 2018

At PPMA 2018, visitors to the Sick UK stand will learn how technology developments in smart sensors and machinery safety systems can release latent productivity benefits that help engineers to aggregate ‘marginal gains’ and achieve significant yields in efficiency, throughput and reduced waste.

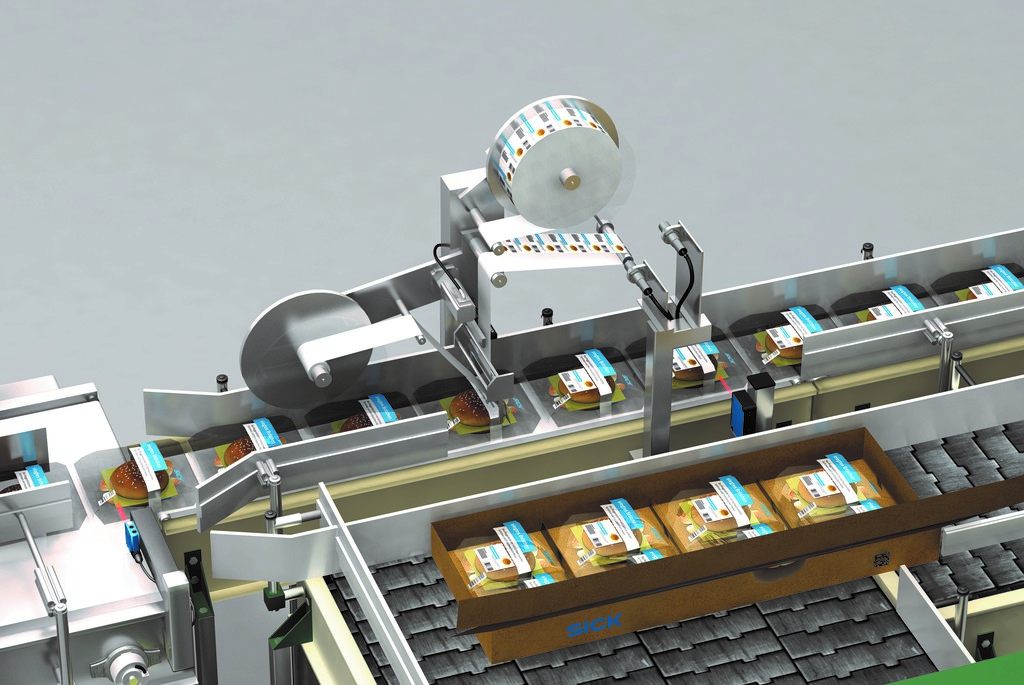

Sick will be showcasing its 2D and 3D vision sensors, as well as its comprehensive range of Auto-Identification solutions for coding and labelling to demonstrate how high-performance detection, quality inspection and traceability are meeting the challenges of increasingly flexible and digitally-connected production environments.

Solutions including the Sick LabelChecker, an ‘off-the-shelf’ label inspection solution, and the Sick Inline Code Matcher ‘right product, right packaging’ quality control system integrate Sick’s market-leading expertise in machine vision and code-reading technologies to deliver easy-set-up systems with real-time connectivity for trend analysis and system diagnostics.

Visitors will also learn how Sick’s diverse range of registration sensors yield efficiency advantages through reliable detection and control of packaging processes such as cutting, folding and glueing. From contrast to colour and luminescence, no substrate however shiny, matt, dark or uneven is a challenge too far for Sick.

Sick will also be demonstrating solutions to machinery safety that protect employees whilst enabling them to work faster, with less downtime and in more effective collaboration with the machines they are operating. Sick’s safety laser scanner, including the MicroScan3, a full range of safety light curtains and Flexi-Soft safety control system will all help engineers to achieve compliance while optimising productivity.

Sick will also be demonstrating how its level, pressure, flow and temperature sensors realise optimised processes though accurate measurement and control. Sensors like the LFP Inox level sensor combine accurate measurement with robust reliability in harsh, hygienic environments.

Seb Strutt, Sick UK senior product manager explains: “The notion of winning through ‘marginal gains’ has been pioneered by elite sports teams with remarkable success. Hunting down opportunities to uncover hidden potential across a wide range of parameters can add up to a powerful cumulative advantage over the competition.

“Industry 4.0 is not really a revolution at all – it’s all about uncovering buried treasure in your production processes. Every single discovery can add up to a productivity advantage, whether in the form of quicker product changeovers, more consistent quality in labelling and packaging or reduced customer fines and returns. Effective vision sensors eliminate the waste associated with incorrect portioning or rejects. With smart sensors on board, engineers can improve predictive maintenance and reduce their stock inventories.” Stand A26

- RFID-monitored safety lock

- Fill level monitoring

- Intelligent solutions showcased

- Easy, standalone RFID

- Powerful and compact cube sensor

- Closer human robot collaboration

- Sensors showcase

- Lightgrid reinvented as versatile 'light chain'

- Packaging sensors that always see the light

- Safety-certified encoder