|

Charlotte Stonestreet

Managing Editor |

Editor's Pick

Tech start-up to half the cost of CNC machined parts

12 July 2019

London-based CloudNC has launched what is being hailed as a new era for CNC machined parts with the opening of the first of several planned UK factories offering aerospace-grade quality at a fraction of the price of existing alternatives.

In what has been dubbed a step-change for CNC machining, the company has set its sights on rapid global expansion into the £100bn global industry responsible for the manufacture of parts for everything from the aircraft and automotive industries, to consumer, medical, defence, and oil & gas applications.

At the heart of the new approach is breakthrough AI software developed by CloudNC which shortens the programming time for CNC machining of parts from days or weeks of an expert’s time, to just a few minutes - with no expertise required. The software also leverages the huge computing power available in the cloud to vastly reduce machining cycle times over what is currently possible, resulting in a corresponding reduction in production cost. These two advantages combine to enable breakthrough pricing whether producing a single unit, or hundreds of thousands.

But there is much more to the start-up than AI software. As Co-founder and CEO Theo Saville explains, CloudNC is entirely focused on building the world’s most efficient, most flexible factories, making machining faster, cheaper and at a much higher quality by applying the best practices of hypergrowth technology companies to manufacturing.

“Starting with a clean slate means we’ve been able to apply a digital-first approach from the outset, without needing to consider integrating existing legacy systems or technologies. Apart from our software, we’re also applying the best industry 4.0 technology available to make Factory 1 as efficient and flexible as possible – and where that technology doesn’t exist, or isn’t mature enough in our sector, we’re designing it.”

Creating the gold standard in manufacturing involves developing a business structure and approach that is more common in hyper-growth tech start-ups than in manufacturing, and CloudNC places a high value on attracting, retaining and developing the best talent across all areas of the business from production to software engineering. After all, says Saville, “technology can’t change the world on its own; it needs to be combined with amazing people who can make it happen.”

Factory 1, which opened in the spring in Chelmsford, Essex, is the first CloudNC factory and the exemplifies the CloudNC approach. Using the best CNC machinery available from the likes of DMG Mori and Mazak, it also applies robotics from Erowa and embraces Industry 4.0 principles of connectivity and automation to deliver a faster, more reliable CNC parts machining experience to customers. According to Saville, “CloudNC is on a development curve that has not been seen in the manufacturing space before. Just six months ago our Chelmsford site was just a couple of guys with laptops and some camping equipment. Now it is a highly efficient, highly automated facility functioning close to capacity and we are looking at Factory 2 and beyond while we continue to implement more autonomous I4 technologies at Factory 1 and apply what we learn at every step.”

CloudNC’s ultimate mission is to provide a service that is fully automated. The pricing, the manufacture; even the raw materials will be shipped in and loaded automatically by robots in state-of-the-art factories. Inspection, verification, packaging and fulfilment will also be carried out autonomously, further reducing the time and cost of CNC parts manufacture for industry. Expert staff will take over only in the most challenging and interesting scenarios.

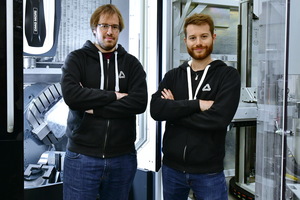

The company was founded in 2015 by CEO Theo Saville and CTO and software engineer Chris Emery. It has grown to employ more than 70 staff including some the world’s leading software engineers and a management team with vast experience scaling tech start-ups to become some of the most successful companies in the world, including the likes of Uber, Betfair, and Fetchr. Also within the leadership team is cutting-edge experience with Industry 4.0 and greenfield assembly of massive scale Aerospace, Space and Automotive operations.

Since launch, the company has benefitted from multiple government grants and support from government agencies including InnovateUK, the Advanced Manufacturing Research Centre (AMRC), the Manufacturing Technology Centre (MTC) and Warwick Manufacturing Group (WMG). CloudNC has also raised more than £11.5 million in Venture Capital (VC) funding to date, from some of the top investors in the world, that it used to develop the powerful AI software from the ground up and open Factory 1 in spring 2019.

Chief Commercial Officer, Rami Saab, says that CloudNC offers a window into the future, “a revolution that is gathering momentum, and it’s coming not a moment too soon for industry” he says. And the best part, according to Saab, is that now CloudNC is operational, “the only thing customers need to do to get a taste for the future for CNC machining is to send us a CAD design for a part or product, and see for yourself how quickly and cost effectively we can deliver a superior result.”

CloudNC CNC machining services can be accessed directly through the website www.CloudNC.com, over the phone on +44 20 3966 8379, or via email at [email protected]

- Solving the productivity puzzle

- Inovance launches industrial robots to European market

- AMR revolution in cold chain logistics

- ek robotics & OTTO Motors announce technology partnership

- Experts appointed to supercharge UK’s AI sector

- Three-fifths of the industrial control industry has not deployed security configuration management

- The hidden impact of harmonics

- The case for augmented reality

- Emerging tech driving circular economy

- What is driving demand for ultra-low voltage motors and drives?

- No related articles listed