|

Charlotte Stonestreet

Managing Editor |

| Home> | IIot & Smart Technology | >Connectivity | >Industrial automation architecture evolution |

| Home> | IIot & Smart Technology | >Networks | >Industrial automation architecture evolution |

Editor's Pick

Industrial automation architecture evolution

18 August 2025

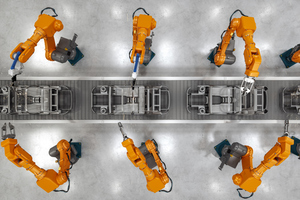

As industrial manufacturers look to achieve more with less, businesses are exploring advanced automation architectures to balance operational efficiency with wider sustainability responsibilities, writes Dave Sutton.

WHILE EVERY manufacturer is different and leverages digitalisation to achieve individual goals, there are certainly some shared goals applicable to the entire sector. Namely, minimising downtime, improving operational efficiency, reducing waste (in all forms), and contributing to the collective sustainability journey of manufacturing. These goals present challenges that are driving changes in the nature of Industrial Automation control systems towards open architectures at an Operational Technology (OT) level. This evolution can deliver value to businesses and their supply chains.

Open architectures

So, what has been driving the need for open automation? The need to overcome the drawback that although traditional proprietary technologies work well individually, they are locked and closed, with code that is not portable.

It is not feasible for manufacturers to immediately replace critical assets as soon as a more advanced version is available. This leaves legacy hardware in place with bespoke software, communications, and hardware, locking users into one vendor. Typical manufacturers with disparate systems from multiple vendors will see this challenge magnified as they advance in digital transformation. Many end users will require substantial industrial automation (IA) system re-engineering as code written to run on legacy hardware is not portable or compatible with new-generation hardware. This hinders the digital transformation of UK manufacturing, holding back capabilities that will improve efficiency behind large cost and time investments.

The answer is to transition to open automation, as is commonly seen in the IT world. Manufacturers are demanding systems that are software centric and hardware agnostic, so that application code is portable to run on a wide variety of hardware from any vendor. This opens communication across different machines, devices, and sensors, enabling operators to work more efficiently and achieve more with less.

This can be achieved by adopting the IEC 61499 universal automation standard, which is a technology enabler defining how to design distributed applications using ‘plug and produce’ software components independent from the hardware on which they execute. The standard is being led by a community of automation users, technology vendors and academics who want to change the game of automation through the non-profit organisation, Universal Automation.Org.

Plant engineers, systems integrators, OEMs, or anyone involved in the manufacturing supply chain, who design, link and support legacy systems can reduce the massive spend associated with servicing individual assets while setting a pathway for continuous improvement.

For example, in a mature industrial sector such as food and beverage manufacturing, it is common to see a mix of new and legacy assets. A challenge for food processors is that consumers base their purchasing decisions on multiple factors, always looking for the next product or flavour in the fast-moving sector. Manufacturers need to be flexible and scalable to respond to the needs of the market, but this can seem impossible when battling proprietary systems. Open automation enables that level of flexibility with less time spent on non-value-adding tasks and more time innovating.

This example can be applied to manufacturers of any size, producing any product, as shown in our recent research paper entitled ‘A quantitative comparison of digitised industrial automation’. This covers the results of field tests showing that software engineering can be delivered three times faster through open automation for standard production strategies, actively increasing flexibility.

Industrial automation systems currently in operation in UK manufacturing were often put in place decades ago. They’re now holding back manufacturers from realising the full potential of digital transformation and the advances in technologies and computing power. The drive for hardware-agnostic platforms presents an opportunity to use industrialised PCs to run operational application code. This development enables the adoption of soft PLCs or Edge controllers, which further fuels the convergence of IT and OT. However, even with manufacturers investing in edge computing technologies to handle the burden of collecting, analysing, and reporting data, the benefits will be limited without an open automation approach that can handle data in a single agnostic platform.

Digitalisation

Across industry, we can see wide adoption of IIoT (industrial internet of things) technologies that offer an immediate improvement for manufacturers but ultimately many are held back from realising true potential due to being unable to fully commit to automation.

For example, adding a sensor to a legacy asset for real-time data collection will reduce downtime by supporting proactive maintenance but is limited without interoperability.

Sharing that same sensor data via an open automation platform extends that proactive maintenance capability through access to data from all sources in the facility, new and legacy. The manufacturer can use that single digital thread to make informed business decisions to enhance uptime, maintenance, and energy consumption without the costly investment of new critical assets.

Unlocking the flow of data throughout a manufacturing facility has driven the deployment of more devices at the network edge. This delivers processing power near the assets to create a distributed architecture that offers increased resilience, availability and maintainability. In comparison, traditional large, centralised control architectures are less able to handle the complexity of modern manufacturing processes, especially as those businesses look to scale and remain flexible.

This has created a growing demand for physical I/O that must be prepared for the data-driven future. A future-ready I/O offering supports universal automation by using open Ethernet protocols to deliver connectivity to a variety of devices and architectures for better performance and availability. Not only will this offer advantages in the short term, it fulfils a promise of universal automation by creating a unified framework for all automation, meaning that architectures created today can evolve with future technologies, once again empowering manufacturers to freely explore any element of digital transformation.

Cybersecurity

Any industrial activity that relies on data connectivity will always come with a cybersecurity concern and this isn’t reserved only for critical infrastructure. Businesses of all sizes are being increasingly targeted and as manufacturers become part of more complex supply chains the attack surface increases.

Just as universal automation is all encompassing so must be cybersecurity, with a strategy that integrates people, technology, and operations. Just because the flow of data has been opened it doesn’t mean there has to be data protection gaps, even with legacy assets that may have exploitable control systems. This has driven the need for solutions that are certified by the IEC62443 cybersecurity standard to safeguard potential vulnerabilities in industrial systems while providing clear guidance on the responsibilities for every level.

Realising the potential of universal automation and digital transformation, means cybersecurity must be considered beyond processes and procedures to encompass every asset or product that is added to the network.

By decentralising and adopting advanced features, manufacturers will see secure data exchange that reduces risk and improves overall resilience, even as cyber-attacks become more complex. This is essential for manufacturers that want to see the benefits of universal automation with minimised risk, always considering the needs of the future while unlocking immediate benefits.

High availability architecture

Unscheduled downtime represents a massive cost for manufacturers of all sizes. The Performance in Focus 2024 report shows that average hourly cost of downtime stands at £5,471.95 drives the need for predictive maintenance and the open automation that enables it.

To address this challenge, and facilitate high availability architectures where downtime cannot be tolerated, manufacturers can use a mix of technologies such as hot-standby processors, redundant switches, redundant I/O, redundant power supplies, module hot-swapping, Change-Config-On-The-Fly (CCOFT), Fast Device Replacement (FDR) built-in diagnostics, and ring network topology.

Future of industrial architectures

Open and universal automation represents the future of industrial architectures, supporting manufacturers as they seek to achieve more with less in 2025. The future-ready approach empowers facilities of all sizes and specialisms to continuously innovate and optimise, looking far beyond single technology deployments and realising the full potential of digital transformation. Universal automation is playing an increasingly important role in UK manufacturing as it continues to digitalise its operations in order to compete on a global scale.

Dave Sutton is product marketing manager for industrial automation at Schneider Electric

- Scaling up for success

- Schneider donates €1m to Factory of the Future

- Schneider Electric launches EcoCare in UK

- Next generation services enabling smarter operations

- Sustainability transformation in manufacturing

- Schneider & AVEVA give Flint factory digital upgrade

- Smart from the start?

- IIoT starter pack competition

- Smart RTU controllers

- Collaboration to improve asset performance

- Phoenix Contact takes over Etherwan Systems Inc.

- EtherCAT control solution

- Protecting rack mount Ethernet switches

- Increased Ethernet network visibility

- The digital future has begun

- Ultrasonic sensor

- Transmission of Data to Cloud

- Makes IoT available in practice

- Education key to unlocking I4.0

- Complete solution for IO-Link