|

Charlotte Stonestreet

Managing Editor |

| Home> | IIot & Smart Technology | >Connectivity | >Complete solution for IO-Link |

| Home> | MACHINE BUILDING & ENGINEERING | >I/O Systems | >Complete solution for IO-Link |

Complete solution for IO-Link

16 August 2017

Omron has added a comprehensive range of IO-Link products to its extensive automation platform, providing users with a convenient and dependable option for implementing complete IO-Link solutions.

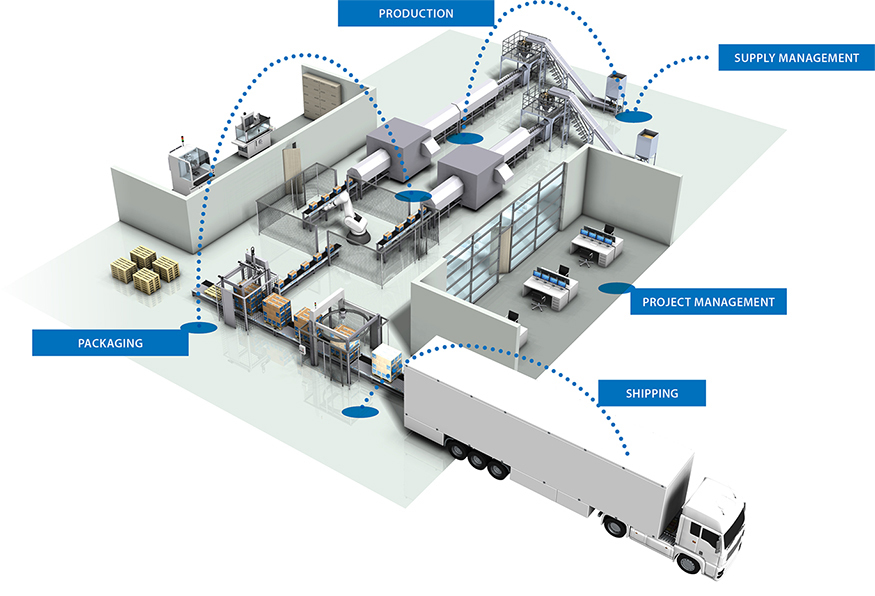

The new products, which include high performance sensors and versatile IO-Link masters, make it even easier to achieve the productivity and efficiency gains associated with Smart Factory solutions.

The new IO-Link compatible sensor range from Omron currently incorporates through-beam, retro-reflective and diffuse reflective photosensors, colour mark sensors, standard proximity sensors and spatter-resistant proximity sensors. All types are available with pre-wired connections, with standard M8 connectors or with M12 Smartclick connectors that offer faster and more convenient installation.

The many innovative features offered by the new sensors include the ability to continuously monitor and report their own performance and support on-the-fly reconfiguration using data transferred by the automation system.

The sensors are complemented by two IO-Link master modules, one with screwless clamp terminals for use with pre-wired sensors, the other with Smartclick connectors. Both master modules allow the connection of standard sensors, as well as the new IO-Link types, making it easy to upgrade existing machines and systems.

IO-Link is an open international standard supported by more than 100 companies, including major sensor manufacturers. It provides bidirectional communication and, as well as supporting typical sensor and actuator signals, it also allows the sensors and actuators to exchange status information and operating parameters with the automation system.

This means, for example, that a sensor can generate an alert when its performance starts to fall off because of the build up of soiling, allowing this to be corrected before it results in a machine stoppage. The ability to send new parameters to the sensors is particularly useful in machines that handle more than one type of products as, in many applications, it eliminates the need for manual intervention in changeovers.

Omron’s new IO-Link products are part of the company’s total automation platform, which also includes support for EtherCAT and EtherNet/IP. For seamless integration, IO-Link products are included in Omron’s Sysmac Studio software environment, which provides comprehensive facilities for configuring, programming, simulating and monitoring automation systems.

- Machine interface

- Flexible & intuitive operation

- Automation platform expanded

- Selecting a mobile robot for heavy loads

- Modular I/O For Real-Time Machine Control

- Cobot palletising solution

- OMRON invests in Taiwanese collaborative robot company

- Robotics & the potential for the lights-out factory

- Food for thought

- Image inspection & code verification

- IMPROVED RESPONSE TIMES

- NO COMPRESSOR TO MAINTAIN

- DISTRIBUTED MODULAR I/O - ANSWERS & QUESTIONS

- All-in-one safety solution

- Modular I/O For Real-Time Machine Control

- EtherCAT I/O is Tightly Integrated into Aerotech's A3200 Automation Machine Controller

- Efficient heat dissipation

- Measuring systems with IO-Link

- Slimline I/O system

- Accurately picks up analogue signals