|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Chains | >Compact tool changing solution |

Editor's Pick

Compact tool changing solution

25 November 2013

Tool changing devices for machine tools are often standard bulky chain driven systems that, in many cases, take up excessive space in the body of the machine.

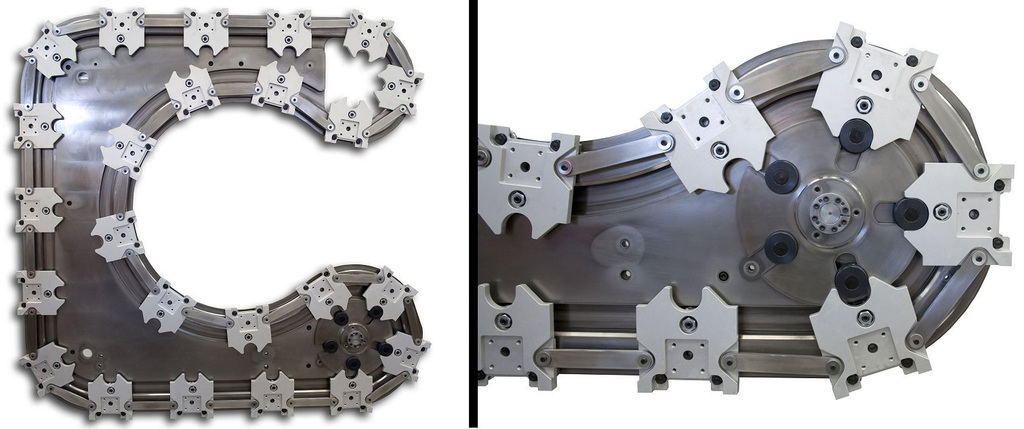

While addressing this issue, 1-Trak from HepcoMotion, is also said to be more than just a space saving tool changing solution. The combination of precision positioning offered by this play free vee guidance system, coupled with the ability to follow almost any two dimensional shape, is claimed to open up the possibility of new concepts in tool change design.

Systems can be constructed to suit individual loading and rigidity requirements by making the vee guidance track size and shape to suit the application. This is a somewhat unique approach not seen before in tool changing applications.

The main body of the 1-Trak solution is effectively a mounting plate that is designed to be sufficiently rigid to be fitted to any suitable member of the machine structure with the minimum number of fixing bolts. The vee guidance track is machined into the plate as an integral component so there is no requirement for setting. 1–Trak tool changing systems are supplied as a "unit” just requiring the tools to be located to the tool carriages. In turn, these are indexed around the track to the required position through a highly efficient drive system.