|

Charlotte Stonestreet

Managing Editor |

Optimum solution for 24V DC conveyor technology

08 November 2013

Management of 24V drive technology streamlined for system integrators, plant manufacturers and end-users.

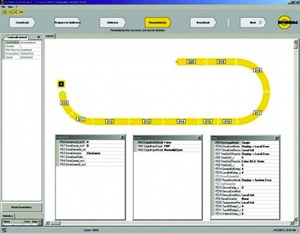

Designed to maximise cost efficiency Interroll’s latest ConveyorControl system can be rapidly installed and commissioned to provide flexible, simple configuration and continuous IP54 protection rating in order to meet the requirements for industrial installations.

The Interroll ConveyorControl focuses on flexible tote conveyor technology and provides a versatile, smart control solution for continuous and zero pressure accumulation conveyors. The key elements of this solution are its mechanically sound, fast-speed 24V 'RollerDrives' with inbuilt controls that can be linked to existing stock control software.

The control platform consists of four different modules, a power pack and the Configurator software that are matched for optimum performance. The independent length of standard ASI cable, incorporating piercing technology, provides for rapid, safe and low cost installation on site.

Each zero pressure accumulation roller conveyor is divided into zones, with the length of each zone being determined by the size of the goods to be conveyed. With conventional technology, segmentation of conveyor systems usually involves the use of a central drive for one long roller conveyor, which runs constantly and independently of throughput volumes. This means the system constantly consumes energy and unnecessarily increases the degree of wear and tear on the system, even when nothing is being conveyed.

The Interroll ConveyorControl system, based on individual zones driven by RollerDrives, only activates to power the actual zones when and where there are totes to be conveyed. Such switching on and off of decentralised drives according to need is a key factor in achieving the enhanced energy efficiency of such a conveyor system and reduces the associated time and cost spent on maintenance. Depending on the mechanical components used, a three to four time’s greater lifespan can be expected when a ConveyorControl concept is in place – a significant factor in reducing the overall cost of any system.

- Distribution centre automated

- Interroll cancels appearance at LogiMAT

- New Smart Pallet Mover from Interroll

- High-performance crossbelt sorter

- Powerful synchronous drum motor

- Drum motor design is on a roll

- Tyre sector drive solutions

- Innovative drive solution

- Conveyor components & integrated drive solutions

- Fully automated material flow

- Reduce Fault Times

- Vision Control Makes The Cut

- MULTIPLE PROTOCOL CONVERSION

- MAKE SURE YOU CATCH THE RIGHT BUS

- Smarter, Faster & More Compact Robot Controller

- What Does Windows 8 Mean For Test & Measurement?

- Thyristor Stack Controllers

- Easy To Automate

- Understanding Thyristor Control

- Introduction to embedded control and monitoring webcast