|

Charlotte Stonestreet

Managing Editor |

| Home> | DRIVES & MOTORS | >Synchronous Motors | >Powerful synchronous drum motor |

Powerful synchronous drum motor

28 June 2017

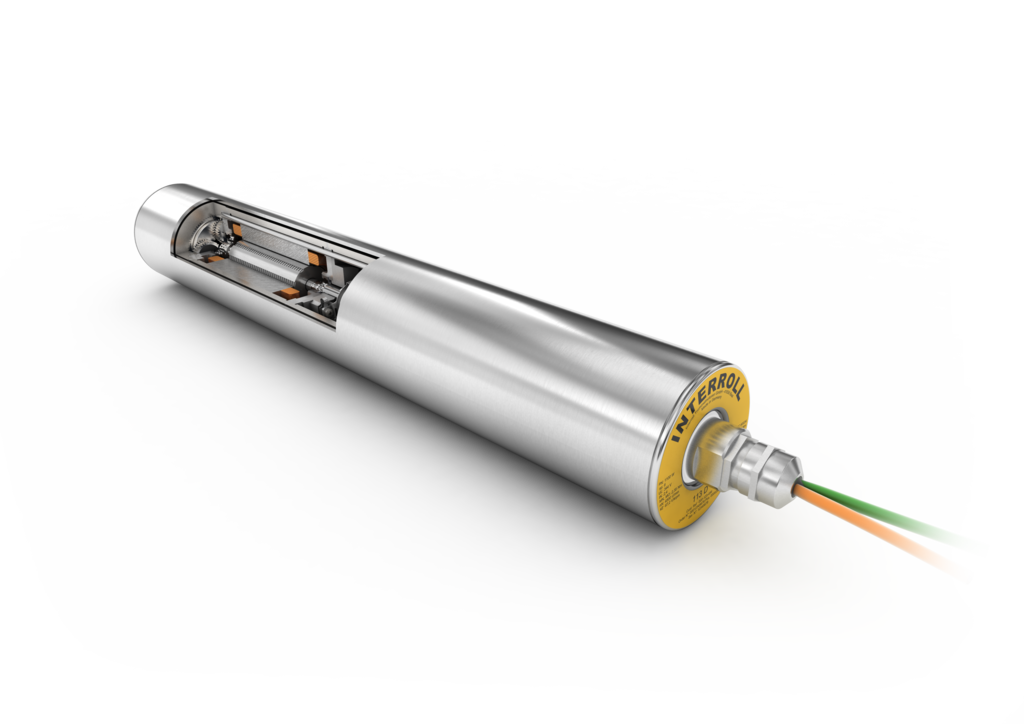

The Interroll Group has launched what is said to be the world's most powerful synchronous drum motor for belt conveyor systems, with a proven output of up to 1.1 kilowatts. High torque and belt tension make it suitable for high applications.

The new motor allows for belt speeds of up to 3.34 meters per second, and effortlessly tackles steep acceleration and braking ramps. The drive is manufactured entirely from stainless steel, meaning that the food and pharmaceutical industries in particular are provided with a drive solution that meets the highest hygiene standards.

When compared to solutions with traditional gear motors, the cleaning and disinfection times are reduced by up to 30 percent. The construction and design of the fully enclosed drive comply with the directives of the European Hygienic Engineering & Design Group (EHEDG). In order to also comply with the strictest of requirements, the drive uses only materials that are certified in accordance with the specifications of the US Department of Agriculture (USDA), the US Food and Drug Administration (FDA), and the EU directive EC 1935/2004.

The construction of the Interroll synchronous motors helps to achieve high levels of energy efficiency. These motors display a loss of performance of just nine percent. A planetary gear that is manufactured from hardened steel transfers 92 to 95 percent of the available power directly to the relevant conveyor system, and drastically reduces the energy requirement when compared to alternative drive systems.

Synchronous drum motors from Interroll offer high output and high torque. They provide maximum acceleration and braking performance with an extremely low level of energy consumption. The motors work at a low operating temperature and stand out thanks to a high start-stop potential for conveyor systems in various industrial sectors such as food processing, the packaging industry and dynamic weighing technology, and other logistics applications. Thanks to its compact design, extremely small outer diameters can also be implemented. This means that users can convey a wide range of products on one single system.

- Modular drum motors

- Study compares drum & gear motors in food industry

- Interroll establishes new service organisation

- Interroll showcases solutions to store & convey efficiently

- Magnetic speed controller

- Energy efficient & powerful

- Now manufactured in Europe

- Interroll expands performance range of synchronous drum motors

- Enables zero-pressure pallet conveyance

- Expansion of drum motor platform & conveying solutions

- High Speed, Low Vibration

- HIGHER TORQUE

- Fast Payback In High Power Applications

- Synchronous PM Motors - IE4

- Production line upgrade

- Natural ventilation permits wider use of torque motors

- Permanent-magnet motor surpasses IE4 standard

- IE5 efficiency without rare earth magnets

- Interroll raises profile

- Reliability issues solved