|

Charlotte Stonestreet

Managing Editor |

Tool changing solution

20 April 2015

When Walter Maschinenbau wanted to develop a new CNC controlled Helitronic tool grinder it needed a product that could link 12 or 24 x 254mm diameter grinding discs and traverse them around a circuit without them clashing within a limited space. The solution came in the form of HepcoMotion’s 1-Trak system, which allows any two dimensional track shape to be produced.

Whereas PRT track systems have standard end segments of the same diameters linked by straight slides, 1-Trak allows a bespoke shape to be produced. Fitting into the available space and preventing the discs from clashing meant a number of hours using CAD software, developed by HepcoMotion, to plot the required circuit for the discs.

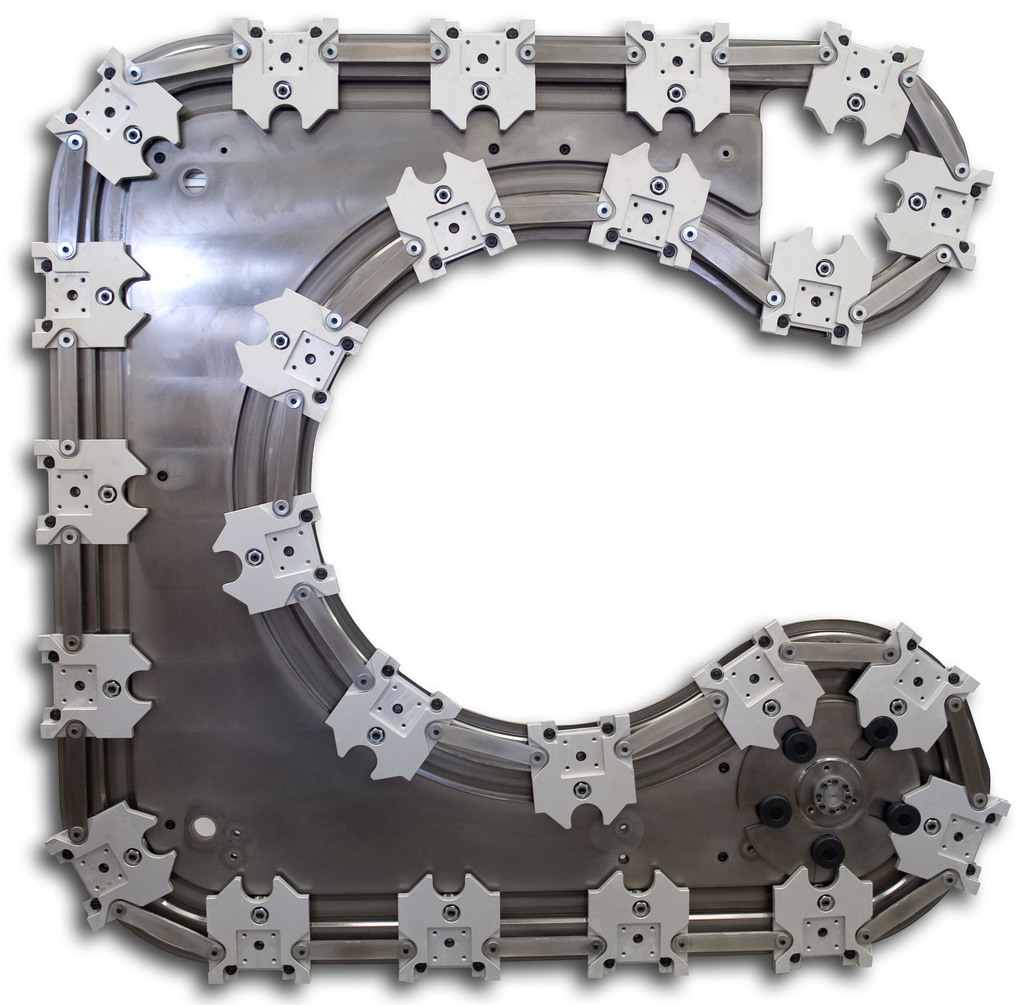

The final shape for the 12 and 24 carriage systems, to prevent the discs from clashing, was somewhat different as the same length space restrictions existed in the machine for both options. In the 24 carriage case there was vertical room available and this was utilised by the final C shape of the system.

The 1-Trak system was produced from a single plate of specialised material so that there was no assembly of track parts required. The plate included the vee track machined in, plus the cam profile for the carriage drive pins to follow. A drive wheel with slots to allow the pin movement was driven by a helical bevel gearbox attached from the rear of the plate.

To achieve the motion around the track with either 12 or 24 carriages there needs to be a small amount of clearance at each link attachment; this potentially could have been problematical in achieving the positional accuracy tolerance of 0.050mm. A pneumatically operated locking device physically locks the carriage in the stopped position, ensuring a positional accuracy of 0.030mm is achieved.

Very little maintenance is required for any of the parts; the Hepco standard bleed lubrication system for the track was installed to ensure a measured amount of lubricant was distributed to the vee guide. The life of the system is many thousands of kilometres service and if eventually, during the life of the machine, bearing wear is evident it is a simple task to change the vee bearings within the carriage.