|

Charlotte Stonestreet

Managing Editor |

Greater process consistency

07 November 2013

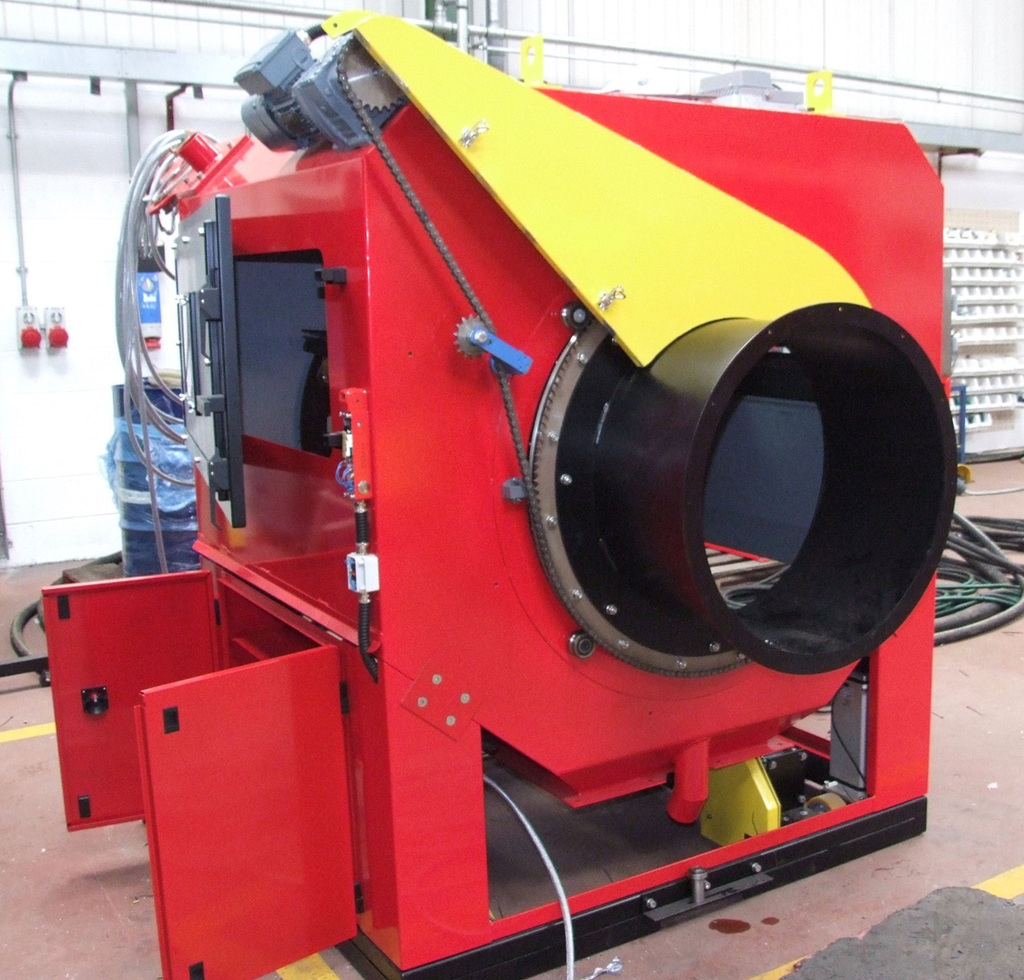

Pipeline Induction Heat (PIH) is using two PRT2 360° precision ring systems from HepcoMotion to move three blast heads around oil pipe field joints and provide a key for subsequent coating.

The concept has not only reduced the labour cost of a previously manual operation, but delivered far greater process consistency.

The PRT2 Precision Ring and Track system is a friction-free, debris-tolerant system that combines ring segments and straight slides to achieve an almost limitless variation of open paths and closed circuits.

It matches the requirement at PIH as the rings provide effortless guidance around the periphery of the pipe, which also moves through the PRT2 ring centre. This feature means the entire external surface area of the pipe can be assessed and blasted.