|

Charlotte Stonestreet

Managing Editor |

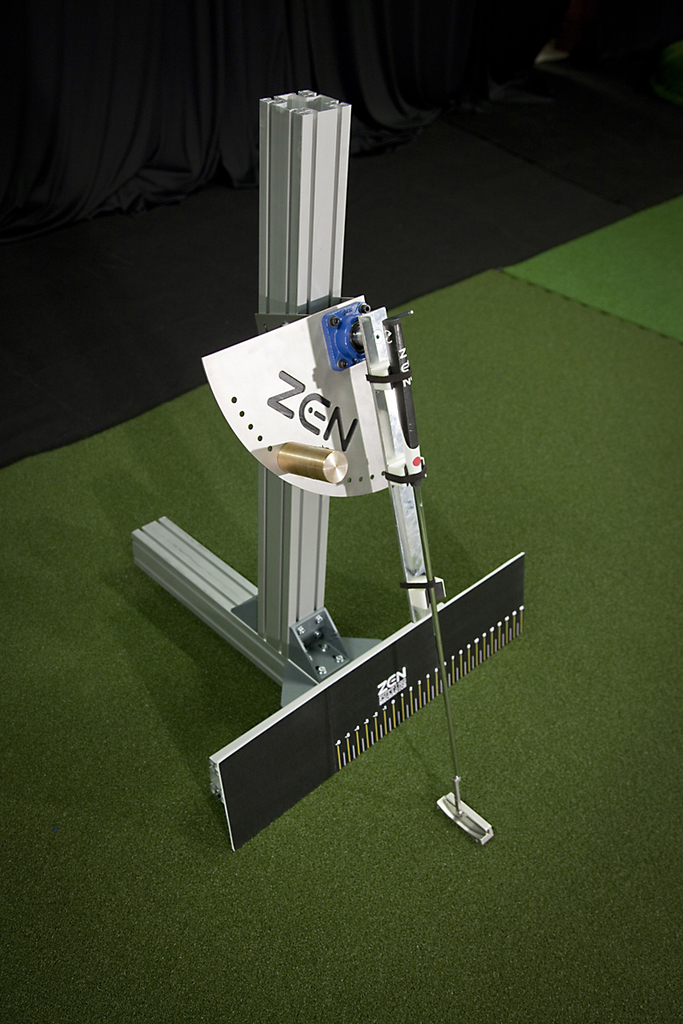

Machine framing hole in one

19 October 2015

The engineers at Zen Putting Mechanics have been helping Today’s Golfer magazine to test 46 putter designs from several top manufacturers with specific parameters to determine the best buys. For one of the tests, the British golf innovator has developed a putting robot with Sheffield University’s AMRC – Boeing research centre that evaluates a putter’s ability to forgive off-centre strokes.

After successfully using MiniTec UK’s Profile System for the adjustable frame on its ‘Green Stage’ variable contour putting platform, the team once again specified the modular and adaptable aluminium profile based machine building system to provide a stable frame for the putting robot.

The MiniTec frame supports the rotating mechanism that grips the putter and is adjusted to simulate a straight swing, guiding the golf ball on a flat level surface. Two putts of around 20-feet were recorded. The first putt was set up to strike the ball centrally on the sweet spot of the putter but the second shot adjusted by a quarter ball into the toe – an apparently common and realistic off-centre mishit. The results - distance shortfall, out-of-line offset - reveal the forgiveness factor after some number crunching.

MiniTec’s modular aluminium profile based machine building system includes thousands of components such as links, hinges, handles, locks, feet, wheels, panels and more - as well as control system and motion components for electrical, pneumatic and hydraulic automation.

- Pallet Circulation

- Innovative camera rig

- Raise your profile

- From simple frames to factory automation

- Industrial meccano

- Machine framing & mechanical safety systems combine for reduced TCO

- Shortlisted for medium-sized business award

- Raising funds for new cancer centre

- HIGH PROFILE JOB AT SOLAR PANEL CENTRE

- Workstations with Scan2Light