|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Equipment | >Ahead of the curve |

Editor's Pick

Ahead of the curve

18 December 2015

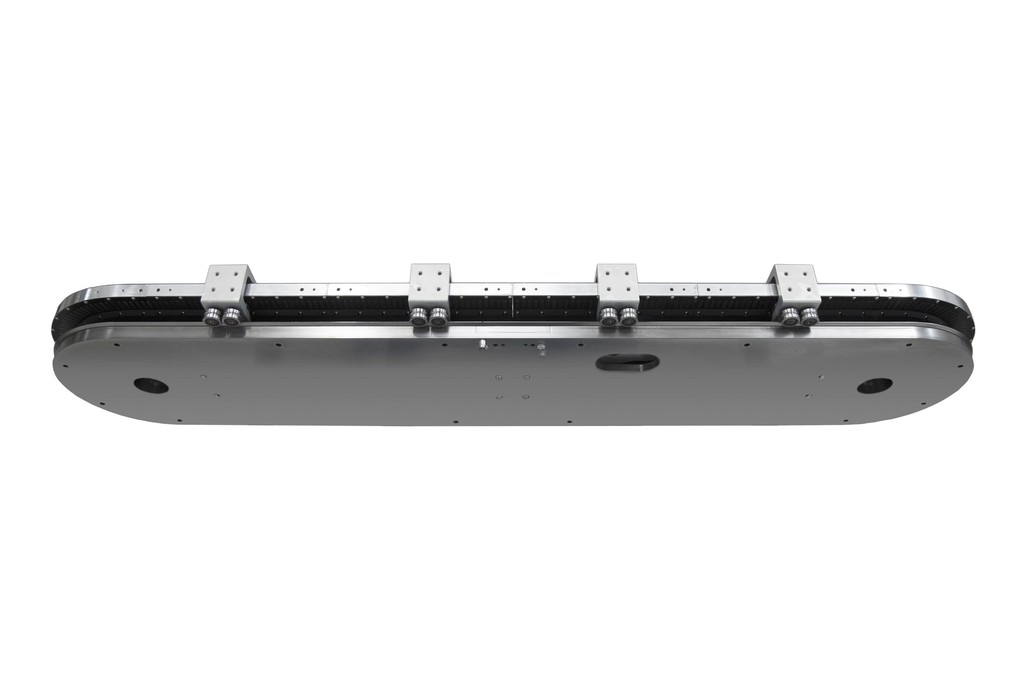

HepcoMotion has introduced a solution that complements Beckhoff’s linear motor transport system. It utilises Hepco's PRT2 and 1-Trak guidance systems to work with Beckhoff’s XTS circuit linear system to meet the needs of higher duty XTS applications where motion profiles and long term durability requirements are particularly demanding.

Beckhoff’s XTS motion system consists of modular linear motors with integrated power electronics and displacement measurement for up to 40 wireless movers on one system. The length of the track and shape can be made to suit the application, making it highly versatile.

The motion of each mover is independently controlled via Beckhoff’s TwinCAT software, allowing users to make product changes on the fly and to implement small lot sizes quickly with maximum efficiency. Mechanical reconfiguration is not necessary as XTS replaces expensive mechanical devices with flexible software functionality.

HepcoMotion has developed special versions of its PRT2 and 1-Trak guidance systems to work with XTS. With a proven track record, Hepco’s guidance systems offer long life, precision and flexibility in a wide array of applications and industries. Featuring V guide technology that Hepco originated over 35 years ago, the PRT2 is provides combined circular and linear motion, while highly 1-Trak system is claimed to re-write what is possible with linear and rotary motion.

The use of Hepco’s advanced linear guidance system provides high levels of support and guidance for the movers, meeting the needs of higher duty XTS applications where motion profiles and long term durability requirements are particularly demanding. All of this is possible without compromising positional accuracy over the life of the machine.

The 1-Trak guidance system can be configured to follow any 2 dimensional path and making it well matched tomany of the XTS system configurations. The XTS is claimed to require very little maintenance to achieve consistent high performance – users will be able to plan routine maintenance into the machine schedule. XTS benefits from monitoring software that detects any changes to the performance of the movers, such as play or excessive friction. This feature is very useful as an early warning for potential bearing wear.

HepcoMotion track systems are hard wearing, and it would be typical in a system operating on a 24 hours per day, 6 days per week basis for the V bearings to have a design life of several years.

- Eagle Has Landed Exhaust Business

- Infra-Red Drying System

- INTELLIGENT FEED

- Modified Atmosphere Sandwich Packing

- Precision Fluid Dispensing

- Rockwell Automation expands Midrange system portfolio

- Jet dispensing system offers speed & accuracy

- Mitsubishi to host food & beverage conference

- Precise, repeatable & energy efficient

- LED line & bar illumination