|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Inspection | >Automated car body inspection |

Automated car body inspection

17 June 2016

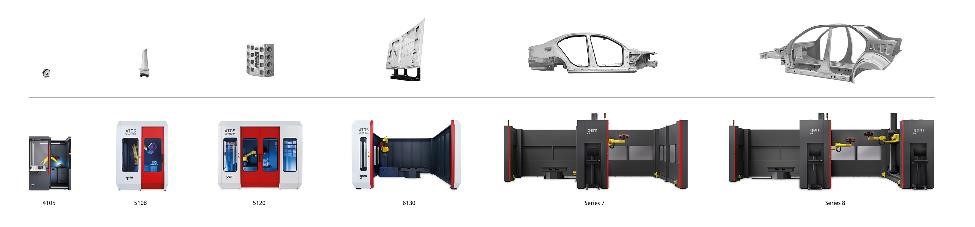

Based in Braunschweig, Germany, Gesellschaft für Optische Messtechnik (GOM) is expanding the ATOS ScanBox series. Series 7 and 8 are suitable for automated 3D digitizing and the inspection of large sheet metal parts such as side panels or complete bodies-in-white.

The new optical measuring machines can be set up and taken into operation flexibly at different locations in press shops and body plants – without permanent fixing or complicated floor anchoring.

In contrast to conventional systems for the measurement of large components, which consist of heavy robots mounted on long rails, the new ATOS ScanBox systems extend the working range of the ATOS measuring head by introducing new robotic kinematics. GOM’s 8-axis kinematics – a combination of a horizontal rail, a vertical lift and an articulated robot – allows high flexibility in positioning the ATOS sensor. As a result of these 8 degrees of freedom, the components can be measured from any perspective – including interiors where space is at a premium.

- No related articles listed

- STAINLESS STEEL SENSITIVITY

- EXTEND MOBILE INTO MAINTENANCE

- Thermal Imager At Reduced Price

- Protect Plastics Production

- THAT TAKES THE BISCUITS

- BROAD CAPABILITY

- Free Pressure Module or Gauge

- Combine SCADA and asset maintenance on a mobile device…with EXTEND7000 for IBM Maximo

- Troubleshooting Simplified

- Vibration Meter