|

Charlotte Stonestreet

Managing Editor |

Performance & efficiency

15 February 2017

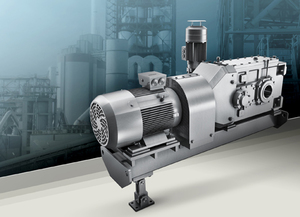

For applications where bulk materials need to be reliably transported several meters high, Currax offers its fully redesigned bucket elevator drives.

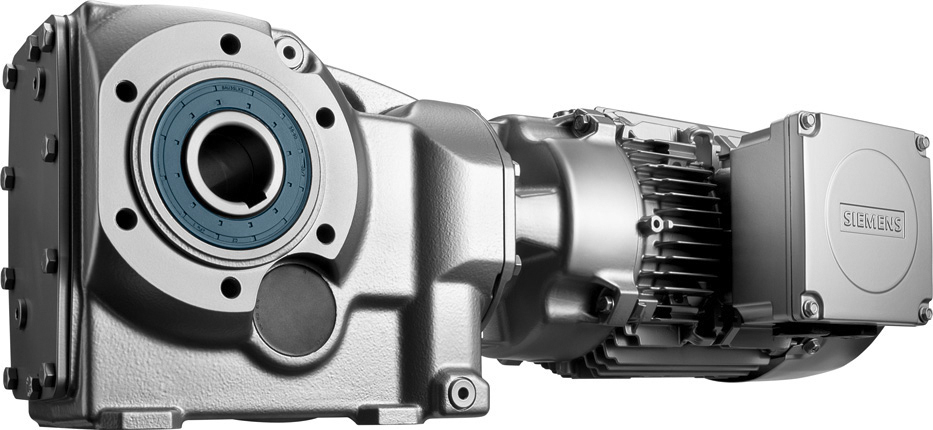

“Thanks to the new SIMOGEAR auxiliary drive, we are opening up completely new avenues of energy-saving and wear-resistant conveyor technology to our customers. The new geared motors enable operators to better harness potential savings in the vertical conveyor systems,” says CURRAX CE, Daniel Assmann.

The Siemens Simogear Geared Motors spectrum comprises all common types, such as helical, parallel shaft and helical bevel geared motors, and features a particularly small construction volume notwithstanding their high torque. The standard range covers a power spectrum from 0.09 kW to 15 kW and gearbox nominal torques of up to 1,850Nm.

Since its connection dimensions comply with market practices, Simogear is fully compatible with the currently used standard. Key impressive aspects of the series include its high energy efficiency as a result of the shank pinion principle and its compact design due to the aluminum housing and integrated end plate.

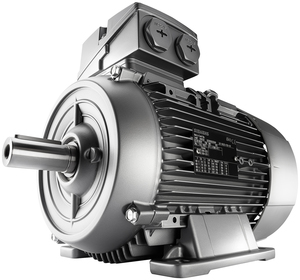

The bucket elevator unit designed by Currax meets the consistently high quality requirements of its individual components. The Simotics GP Motor series features a particularly low weight and dynamic design, ensuring maximum flexibility. In this regard also, the IE4 motors offer huge energy saving potential in the highest defined motor efficiency class, and stand out due to an efficiency level of up to 14% higher combined with low losses.

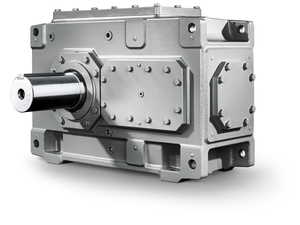

As a comprehensive set of components, the well-known Flender gear units can be tailored individually to customers’ requirements. The portfolio ranges from universal standard gearboxes and application-specific gears to customized solutions. It includes helical and helical-bevel gearboxes as well as single- and multi-stage planetary gear units. Thanks to a broad spectrum of gear transmission concepts and designs, the model series offer an almost infinite variety of design variants in a torque range of approx. 2000 to 2600000Nm.

Currax offers the cam clutch N-EUPEX made by Flender Siemens as coupling for a complete bucket elevator drive. This features outstanding torsional flexibility and damping properties, enabling shaft misalignments to be compensated. The fail-safe coupling ensures maximum operational safety and is available in 23 sizes. The torque range extends from 19 to 62000Nm.

Daniel Assmann says: “The optimally matched components of the drive are particularly suited to the demands placed on conveyor systems in harsh environments, such as dust absorption. Designing robust and powerful drive units while optimally harnessing energy efficiency potential – that’s Currax.”