|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Pumps | >Consistent coolant delivery |

Consistent coolant delivery

14 August 2018

Wanner International will be exhibiting the latest developments in high-pressure coolant delivery on stand 8E78 at AMB Stuttgart.

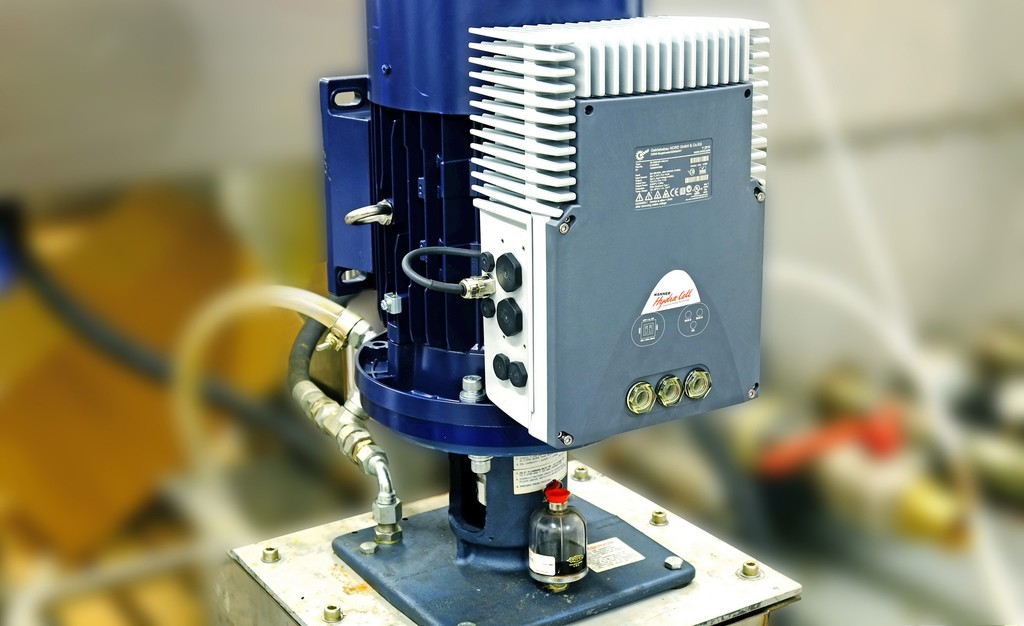

The Company’s Hydra-Cell pumps are claimed to reduce costs and improve productivity thanks to their seal-less design. Able to handle the fines that can destroy pumps with dynamic seals, Hydra-Cell pumps require no fine filtration. They need minimal maintenance and can even run dry indefinitely without damage.

Being a true positive displacement pump with no internal flow losses, Hydra-Cell pumps have efficiencies of 78% - 90% (pump shaft to hydraulic power) resulting in significant energy savings; efficiencies that are maintained year after year.

Hydra-Cell’s seal-less design ensures there is no reduction in flow rate with increasing pressure, especially with low viscosity coolants.

Also featured will be the Hydra-Cell intelligent pump, a stand-alone system with minimal machine interface that can maintain a set pressure for all tools in the carousel without the need to bypass coolant when the smaller tools are employed; saving energy and cost while keeping the coolant cooler.

The intelligent pump can also be fully integrated into the machine control system through a range of fieldbus protocols, enabling pump performance data monitoring and reporting. AVP (Automatic Variable Pressure) Control enables each tool can have the desired pressure of coolant regardless of the tool’s orifice quantity or size.